Technical Standards For Marine-Grade Stainless Steel Cabinets: Engineering For Corrosion Resistance

In deck environments where salt spray and high humidity intersect, the material specification of the control cabinet directly determines the lifespan of internal precision components. Top-tier marine VFD control cabinets must utilize 316L stainless steel for the enclosure, paired with high-standard brushed finishes to isolate oxidative stress at the physical level.

Advanced Sealing and Pressure Equalization Technology

High-end enclosures go beyond ip66 protection. They feature integrated, cast-in-place pu foam gaskets that maintain elasticity under extreme temperature fluctuations. Furthermore, to combat pressure differentials caused by internal heat, these cabinets integrate professional breathable vents (pressure compensation devices). This allows air molecules to flow and balance pressure while blocking salt-laden water molecules, preventing moisture from being "siphoned" into the cabinet.

Physical Anti-corrosion and Adaptive Micro-environment Management

Beyond the 316l material, the enclosure design incorporates a sloped-roof drainage system to prevent standing water. Internally, a sensor network monitors the micro-environment. When relative humidity exceeds critical levels, the system automatically activates anti-condensation heaters. This adaptive management ensures the cabinet remains dry, fundamentally eliminating the risks of electrical creeping and insulation degradation.

Core Component Integration: Building an Industrial-grade Robust Architecture

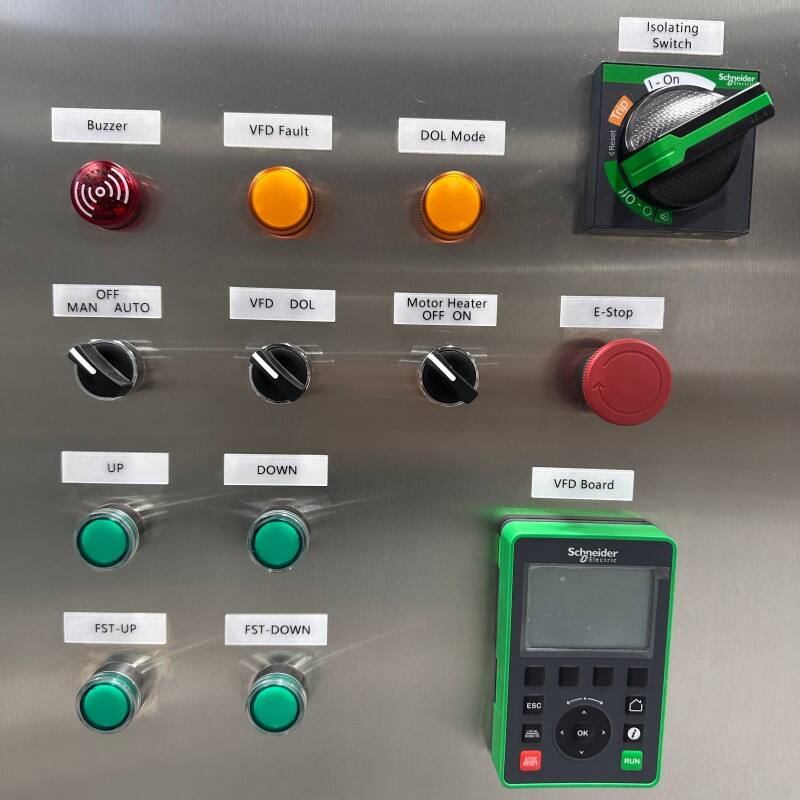

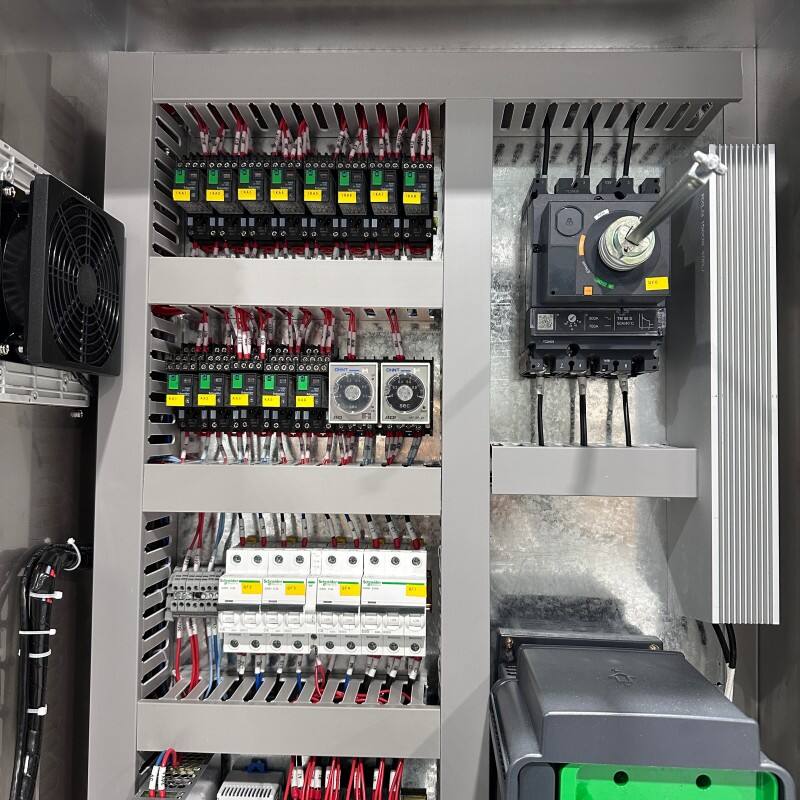

A superior control system is rooted in a world-class supply chain. By integrating schneider electric altivar series vfds, mean well high-end power supplies, and schneider electric tesys contactors, the system gains top-tier electrical resilience and ensures global compatibility and spare part traceability.

Electrical Topology Redundancy and Fault Tolerance

The system integration logic introduces multi-level redundancy. For instance, critical braking contactors and safety control signals are configured with dual channels. Even if a component fails, the system triggers a failsafe mode to ensure the crane stops securely rather than free-falling. This pursuit of "zero risk" is the core support for production managers looking to avoid catastrophic equipment accidents.

Standardized Modular Layout and Efficient Maintenance Interfaces

Internal layouts follow strict modular partitioning, physically isolating high-voltage power lines from weak-signal cables using shielded wiring. All terminal blocks feature clear, laser-printed identification and reserved ethernet communication interfaces. This allows managers to monitor vfd operating current, bus voltage, and energy consumption in real-time, significantly shortening the maintenance window and boosting overall asset efficiency.

Electromagnetic Compatibility and Power Quality Management: Protecting Precision Navigation

In the restricted power grids of vessels, frequent starts of high-power vfds can generate harmonics that interfere with radar, communication, and navigation systems. High-end vfd cabinets must strictly enforce emc/emi standards, featuring high-performance magnetic ring filters and reactors. These components suppress radio frequency interference and reduce current distortion rates. This depth of power quality management protects motors from insulation damage caused by high-frequency pulses while maintaining the electromagnetic purity of the entire ship’s electronic ecosystem.

Automation Logic and Precision Control: Enhancing the Safety Boundary of Crane Operations

Beyond physical defense, intelligent control logic is the key to operational efficiency. Modern vfd cabinets utilize hmi (human-machine interfaces) to achieve stepless speed regulation and precise positioning. The application of soft-start and anti-sway algorithms dramatically reduces mechanical shock on motors and gearboxes. This precise torque control not only improves cargo handling safety but also extends the structural fatigue life of the crane, ensuring every machine equipped with a high-performance vfd remains a reliable asset on the dock or vessel.

FAQ on Marine VFD Cabinet Procurement and Performance

1. How do you ensure the stability of internal wiring in high-vibration marine environments?

Professional marine vfd cabinets utilize spring-clamp terminal technology and vibration-proof cable glands. All wiring undergoes rigorous pull-testing and is identified with heat-shrink markers. This structure effectively resists high-frequency vibrations from ship engines and low-frequency swaying from waves, preventing loose connections that lead to arcing or signal loss.

2. Why is vfd overload capacity prioritized over simple power matching in high-end procurement?

Marine cranes experience loads far exceeding rated states during startup or wave impacts. Leading systems provide 150%-170% transient overload capacity for 60 seconds. This power redundancy is not a waste; it ensures the system does not trip due to overcurrent during extreme load conditions, guaranteeing continuous safety.

3. How does the system handle heat dissipation and temperature rise during high-frequency cycles?

The system employs active thermal management, including high-volume dust-proof fans and optimized internal ducting. For large-power vfds, independent external heat sinks are used. This multi-dimensional cooling ensures the vfd modules operate within their optimal temperature range, significantly slowing down the thermal aging of semiconductors.

4. What is the primary function of the internal cabinet heater?

At sea, temperature swings cause moisture to condense on metal surfaces. anti-condensation heaters, controlled by humidity sensors, maintain dry air inside. This is a critical technology for protecting expensive pcb boards from short circuits and oxidation, marking the difference between standard industrial cabinets and professional marine-grade systems.

5. What are the technical advantages of this integrated system for long-term maintenance?

The system is equipped with an intuitive fault diagnostic hmi that records alarms and provides error codes. Since we use globally recognized brands for all electrical components, local technicians can quickly locate issues and source replacement parts, drastically reducing the mttr (mean time to repair) and ensuring high asset productivity.

Table of Contents

- Technical Standards For Marine-Grade Stainless Steel Cabinets: Engineering For Corrosion Resistance

- Core Component Integration: Building an Industrial-grade Robust Architecture

- Electromagnetic Compatibility and Power Quality Management: Protecting Precision Navigation

- Automation Logic and Precision Control: Enhancing the Safety Boundary of Crane Operations

-

FAQ on Marine VFD Cabinet Procurement and Performance

- 1. How do you ensure the stability of internal wiring in high-vibration marine environments?

- 2. Why is vfd overload capacity prioritized over simple power matching in high-end procurement?

- 3. How does the system handle heat dissipation and temperature rise during high-frequency cycles?

- 4. What is the primary function of the internal cabinet heater?

- 5. What are the technical advantages of this integrated system for long-term maintenance?