Core Advantages and Environmental Adaptability

1. Media Innovation: The Leap from Air to SF6

SF6 (Sulfur Hexafluoride) gas, with its superior molecular structure, possesses dielectric strength and arc-extinguishing properties far exceeding regular air. In a 35kV high-voltage environment, the dielectric strength of SF6 is 2.5 times that of air; at 0.3MPa, its insulation capacity rivals that of transformer oil. This fundamental shift in physical media allows high-voltage conductors—which once required massive clearance distances—to operate safely in much smaller spaces, achieving a "miniaturization" leap in power distribution equipment.

2. Space Optimization: Reducing Infrastructure Costs

Compared to traditional Air-Insulated Switchgear (AIS), 35kV SF6 Gas-Insulated Switchgear (GIS) typically reduces the footprint by 50% to 70%. For urban substations where land is expensive, or space-constrained containerized prefabricated stations, this compact design directly slashes civil engineering costs. By enabling high-density circuit layouts, enterprises can double power capacity without expanding existing rooms, reserving valuable space for future production line scaling.

3. All-Condition Immunity: Ending Geographical Limits

Because the core high-voltage components are fully enclosed in a gas-filled tank, the system is completely decoupled from the external atmospheric environment. Whether in salt-mist coastal areas, thin-air high-altitude mines, or humid and dusty tunnel projects, the 35kV RMU maintains constant insulation levels. This "physical isolation" logic eliminates flashovers and discharge accidents caused by external factors at the source, providing a natural defensive barrier for the equipment.

Procurement Key Indicators: Safety and TCO

When screening suppliers, professional buyers no longer look solely at the initial purchase price. The maintenance-free nature of 35kV SF6 GIS is its greatest economic lever. Since the main switches and conductive parts are sealed in a pressure vessel filled with SF6, internal components are immune to oxidation or corrosion, extending the maintenance cycle up to 30 years. This significantly reduces long-term labor costs and the risk of production losses due to power outages.

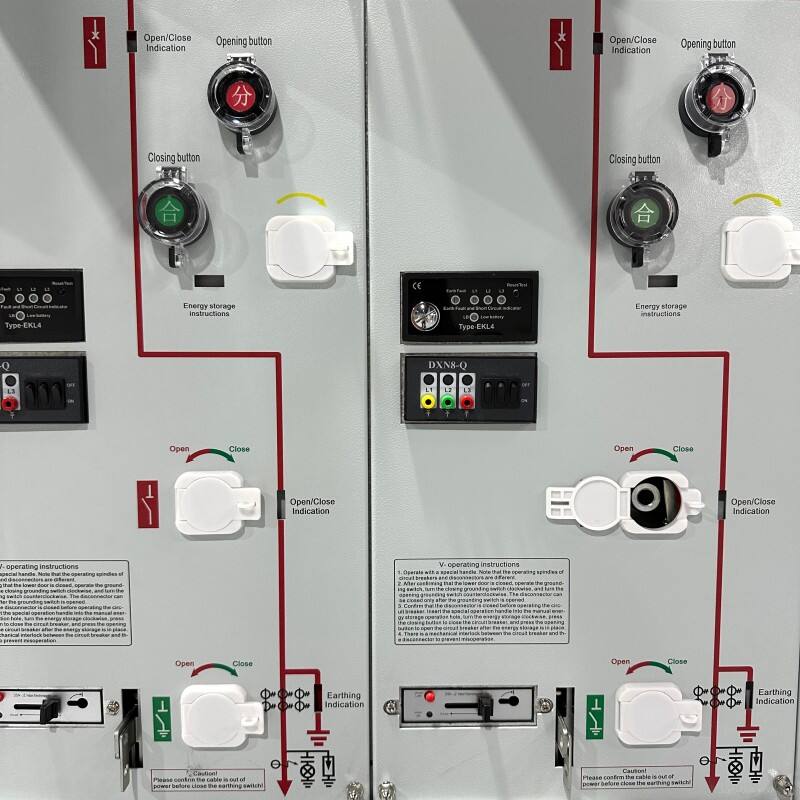

Furthermore, high-quality switchgear must pass rigorous Type Tests, including short-circuit breaking capacity, dynamic/thermal stability, and Internal Arc Tests. For production managers, verifying a reliable pressure relief channel and robust mechanical interlocks is the baseline for ensuring personnel safety and minimizing operational risk. Priority should be given to intelligent units equipped with automation interfaces (DTU/RTU) to meet the growing demand for smart energy monitoring.

Custom Applications in Industrial Scenarios

35kV systems typically serve as the main incoming line for large industrial parks or boost stations for wind and solar farms. Consequently, the configuration (Incoming, Outgoing, Metering, or PT units) must be precisely matched to the single-line diagram. In the wind power sector, the cabinet must be integrated into the tower or compact box transformers, demanding higher temperature control and vibration resistance. Conversely, in urban underground rooms, moisture resistance and low-noise operation become the hidden key procurement metrics.

Manufacturing Standards: Sealing Logic and Quality Baseline

1. Precision Welding: Ensuring Hermetic Consistency

In supplier audits, the welding quality of the sealed tank is the lifeline. Utilizing high-precision welding equipment and strict temperature control ensures that every seam achieves molecular-level penetration and density. This precision control over the heat-affected zone eliminates microscopic pores and stress cracks, locking the annual leakage rate strictly below 0.1%—the foundational pillar for 30-year maintenance-free operation.

2. Vacuum Leak Detection: The Criterion for Longevity

To completely mitigate operational risks, premium manufacturers must perform Helium Mass Spectrometer Leak Detection before the equipment leaves the factory. By utilizing the extreme permeability of helium molecules, even the smallest leak paths are captured. For buyers, this process serves as a critical endorsement of sealing reliability, preventing insulation breakdown caused by gradual pressure loss.

3. Performance Redundancy: Managing High-Frequency Operations

The contact design of the internal main switch determines the system's fatigue resistance. Under high-frequency load switching, the self-energizing arc-extinguishing structure, combined with high-purity SF6, cools and cuts the arc instantly. This "performance redundancy" allows production managers to operate without frequent shutdowns for inspection, significantly optimizing the Return on Investment (ROI) while enhancing reliability.

35kV SF6 GIS Procurement FAQ

1. Why is GIS more cost-effective than AIS in 35kV environments?

While the initial price is slightly higher, the footprint is reduced by over 50%, saving significant civil construction costs. Combined with the 30-year maintenance-free feature, it avoids the high costs of manual overhauls and production downtime caused by environmental corrosion, leading to a much lower Total Cost of Ownership (TCO).

2. How do you verify the hermetic reliability of the tank?

Verify if the supplier uses Helium Mass Spectrometer testing. Additionally, quality units are equipped with temperature-compensated density gauges (pressure gauges) that monitor gas levels in real-time and provide remote alarm contacts for any pressure abnormality.

3. How does it perform in high-altitude or extreme temperature environments?

The fully sealed structure ensures internal insulation is unaffected by external atmospheric pressure (no derating required for high altitudes). For extreme cold, SF6/N2 gas mixtures or heating compensation devices are used to ensure the switch maintains strong breaking capacity at low temperatures.

4. Should I choose a Circuit Breaker or a Load Break Switch + Fuse configuration?

This depends on the protection object. For transformer protection circuits, a "Load Break Switch + Fuse" combination is usually more economical and acts extremely fast. For main incoming lines or large capacity branches, a "Circuit Breaker" is mandatory for its precise, adjustable protection and multiple breaking capabilities.

5. What features should be reserved for future Smart Grid integration?

We recommend pre-installing Current/Voltage Transformers and motorized operating mechanisms, as well as reserving standard communication ports for DTU/RTU installation. This allows the switchgear to support "Remote Signaling, Telemetry, and Remote Control," perfectly integrating with Industrial IoT energy management systems.

Table of Contents

- Core Advantages and Environmental Adaptability

- Procurement Key Indicators: Safety and TCO

- Custom Applications in Industrial Scenarios

- Manufacturing Standards: Sealing Logic and Quality Baseline

-

35kV SF6 GIS Procurement FAQ

- 1. Why is GIS more cost-effective than AIS in 35kV environments?

- 2. How do you verify the hermetic reliability of the tank?

- 3. How does it perform in high-altitude or extreme temperature environments?

- 4. Should I choose a Circuit Breaker or a Load Break Switch + Fuse configuration?

- 5. What features should be reserved for future Smart Grid integration?