When designing a 10kV high-voltage power distribution solution, electrical engineers, project managers, and procurement heads often face a critical decision: should they choose the time-tested and structurally intuitive Traditional Air Insulated Switchgear (AIS), or the higher-performing, more compact Gas Insulated Switchgear (GIS/RMU)?

In modern industrial and urban infrastructure, the "insulation environment" is the lifeline of long-term equipment reliability. In 10kV systems, this difference directly impacts power continuity, maintenance complexity, and overall operational safety. Today, we will focus on comparing 10kV GIS (Carbon Steel Enclosure version) with traditional AIS to help you make the most rational investment choice.

Core Differences: A Revolution in Insulation and Structure

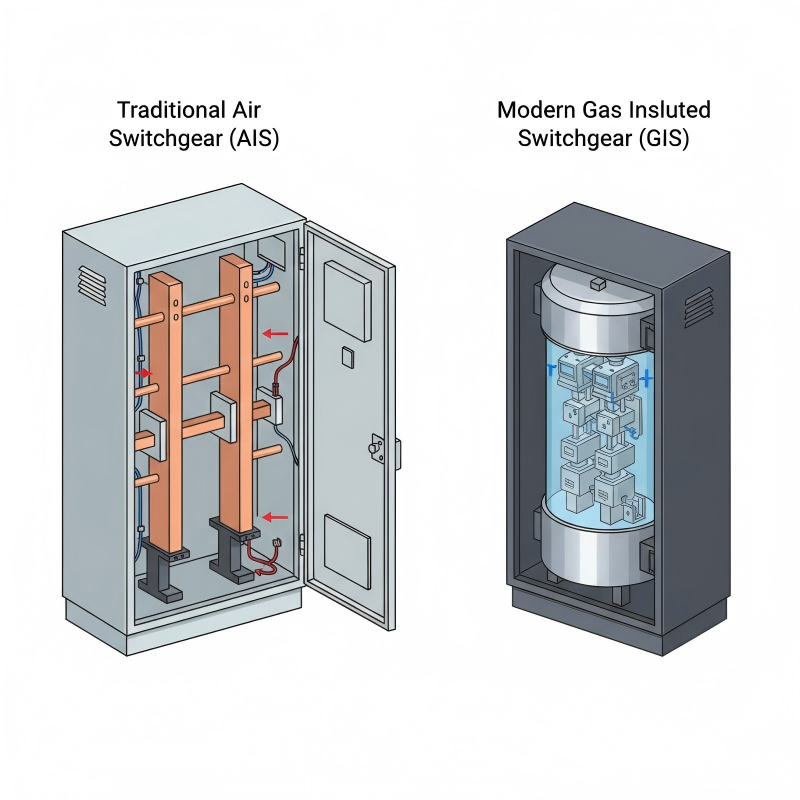

1. The Physics of Insulation Media

Air Insulated Switchgear (AIS): Relies on natural air as the insulation medium between phases and to the ground. Because air’s dielectric strength fluctuates significantly with humidity, altitude, and pollution, wide electrical clearances must be reserved to prevent high-voltage arcing. This results in bulky cabinets where internal busbars and contacts are exposed to air, making them susceptible to oxidation and electrical corrosion.

Gas Insulated Switchgear (GIS): Core high-voltage components (circuit breakers, load break switches, busbars) are sealed within a stainless steel gas tank filled with SF6 (Sulfur Hexafluoride) or eco-friendly gases. Since the insulation and arc-extinguishing properties of these gases are far superior to air, electrical distances can be compressed to a fraction of traditional gear, achieving extreme miniaturization and total enclosure.

2. The "Golden Combination" of Materials and Protection

Our leading solution utilizes a composite structure of a "Stainless Steel Inner Gas Tank + High-Strength Carbon Steel Outer Enclosure":

Core Gas Tank: Constructed from 3.0mm+ high-grade stainless steel plates with robotic laser welding, ensuring zero gas leakage over a 30-year lifespan and protecting core components from external interference.

Outer Enclosure: Made from high-quality cold-rolled carbon steel. Compared to expensive and difficult-to-machine full stainless steel exteriors, carbon steel offers superior mechanical rigidity and structural stability. Through advanced industrial-grade electrostatic powder coating, we save users 15%-20% in enclosure premiums while providing robust impact resistance and a refined industrial finish.

In-Depth Comparison: GIS vs. AIS

Dimension |

10kV GIS (Carbon Steel Enclosure) |

Traditional AIS |

Footprint |

Minimal. Approx. 1/3 the size of AIS; significantly reduces land/substation costs. |

Bulky. Requires large maintenance aisles and safety clearances. |

Environmental Adaptation |

Fully Sealed (IP67 Tank). Immune to condensation, dust, salt spray, altitude, and vermin. |

Semi-Enclosed. Performance fluctuates with humidity and pollution; prone to partial discharge. |

Lifecycle Maintenance |

Near-Zero Maintenance. Switches operate in inert gas; contacts never oxidize. |

Frequent Inspection. Requires periodic cleaning, bolt tightening, and insulation checks. |

Installation Flexibility |

Modular Coupling (e.g., ZLRM6-12V). Factory-preset; "Plug-and-Play" on-site. |

On-site Assembly. Long commissioning cycles; complex busbar connections. |

Total Cost of Ownership |

Higher Capex, Lower Opex. Saves on civil engineering and 20 years of maintenance. |

Lower Capex, Higher Opex. Cheap initially, but risk of costly downtime is high. |

Why Choose Our Carbon Steel Enclosure GIS?

1. Eliminating "Environmentally Sensitive" Fault Risks

In humid southern regions or dusty northern industrial zones, "Condensation Flashover" in traditional AIS is a primary cause of short circuits or even explosions. Our GIS outgoing units seal all live parts. The external carbon steel enclosure undergoes a high-standard powder coating process (tested for 720 hours of salt spray), building a dual barrier of physical isolation and chemical corrosion resistance for stable operation in extreme environments.

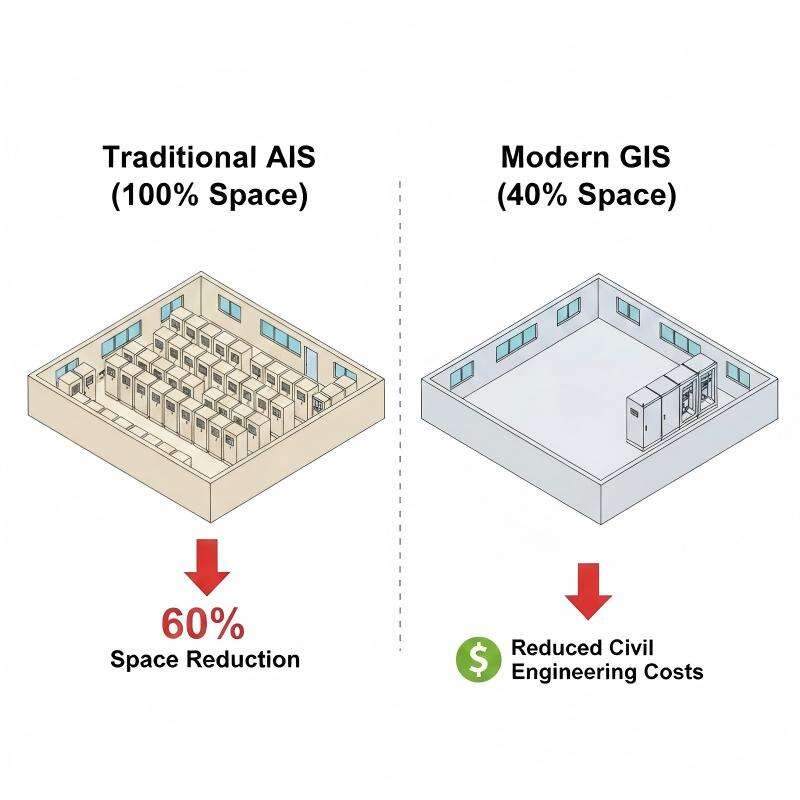

2. Significantly Improving Civil Engineering ROI

For commercial centers, data centers, or high-value industrial parks, every square meter of land is a core asset. Compact GIS can reduce a 100㎡ substation room to approximately 40㎡. This "space-for-money" strategy directly lowers initial civil investment during the project approval phase.

3. Visual Intelligent Operation and Safety

Our outgoing units feature an extremely intuitive interface:

Mimic Diagram: Clearly displays the status of circuit breakers and disconnectors on the panel to prevent human error.

Integrated Microcomputer Protection: Reserved space on the carbon steel panel for smart meters to monitor 3-phase current, voltage, and fault signals in real-time.

Safety Observation Window: Allows confirmation of the grounding switch status without opening the door, ensuring absolute safety for maintenance personnel.

Frequently Asked Questions (FAQ)

Q1: Is GIS safer than AIS during an internal fault?

A: Yes. In traditional AIS, an internal arc can spread rapidly to busbar or instrument compartments. Our GIS seals high-voltage parts in independent tanks reinforced by a carbon steel outer shell. In the event of an extreme fault, the arc is confined within the tank, and pressure is released directionally through a Safety Relief Valve at the bottom, maximizing protection for the operator.

Q2: Can GIS truly be "Maintenance-Free"?

A: The high-voltage core (breakers, contacts) is in constant gas, shielded from erosion, making it maintenance-free for life. Users only need to periodically check the pressure gauge, microcomputer status, and the cleanliness of the carbon steel exterior. This reduces maintenance workload by over 80% compared to AIS.

Q3: How does the carbon steel enclosure handle rust in humid conditions?

A: We use an automotive-grade industrial anti-corrosion coating process. Carbon steel plates undergo degreasing, phosphating, and film pre-treatments before coating to enhance adhesion. The high-standard epoxy powder coating effectively blocks moisture, providing a rust-free lifespan of over 20 years in indoor environments.

Q4: Can traditional AIS still meet modern smart grid needs?

A: While AIS still has a market, the shift toward compact, digitized (SCADA-integrated) grids is accelerating. Due to its size and vulnerability to dust or vermin (causing phase-to-phase shorts), AIS is being rapidly phased out in favor of GIS.

Q5: What are the advantages of GIS in cable connection and expansion?

A: GIS uses fully insulated plug-in cable terminals (European-style connectors), which are safer and more compact than the bare connections in AIS. The modular design allows for future circuit expansion by simply adding units and coupling busbars without major system teardowns.

Conclusion

Selecting a 10kV power distribution solution is essentially an optimization between safety, footprint, and economy. As this comparison shows, Gas Insulated Switchgear (GIS) with carbon steel enclosure technology provides the most forward-looking choice for modern industry—maintaining superior insulation performance while optimizing procurement costs through intelligent material engineering.