102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86 177 0691 9203 [email protected]

Overview

This sophisticated maritime solution is purpose-built to withstand the uncompromising conditions of ocean-going vessels. Serving

as a centralized power management hub, the high-efficiency IP55 marine variable frequency drive system utilizes professional-grade

components to orchestrate complex motor synchronization across the deck. Its 316L housing provides a formidable shield against

salt spray, ensuring the longevity of internal logic controllers during global logistics operations. By incorporating advanced

frequency modulation technology, the hardware maximizes energy efficiency while maintaining superior low-speed torque for

critical load handling. It stands as the definitive choice for operators seeking a reliable vfd control cabinet that merges intelligent

automation with structural durability in high-vibration environments.

Core Components and Features

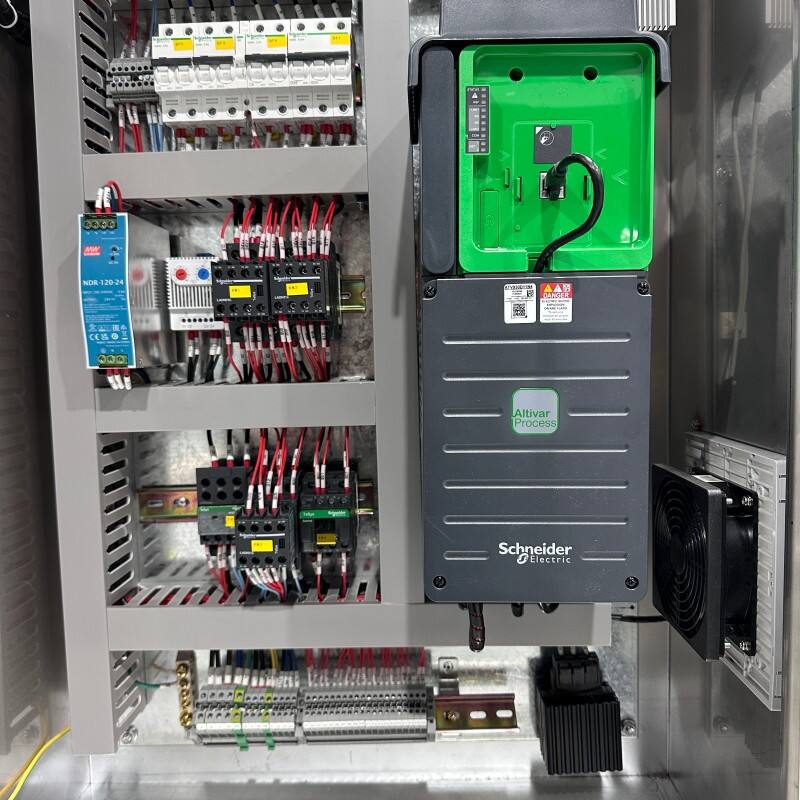

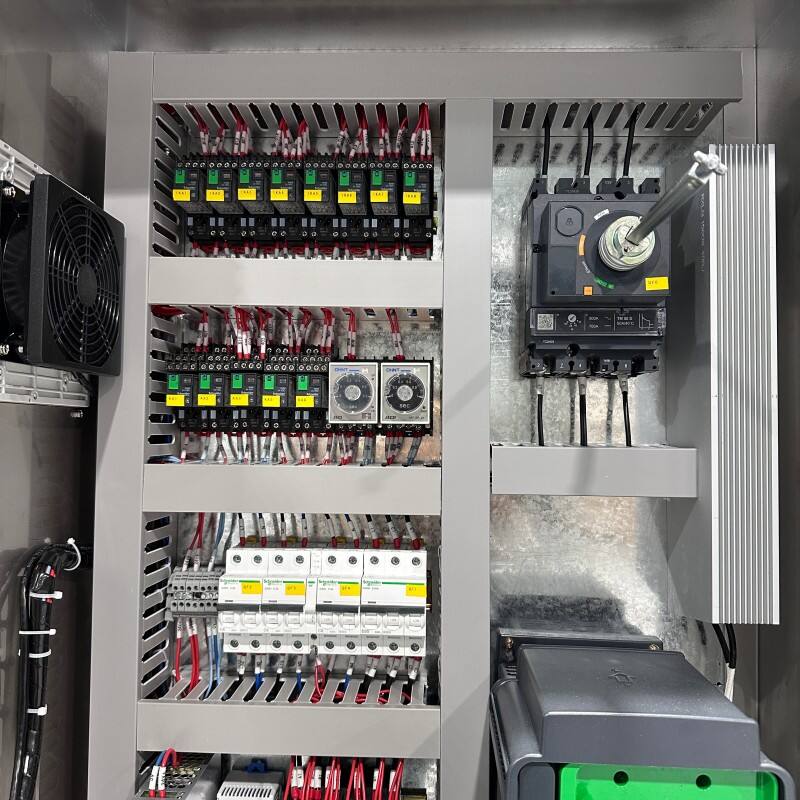

The technical foundation of this assembly is the Schneider Altivar Process drive, an elite component designed for fluid frequency

modulation and energy optimization. As a versatile electrical vfd panel, the system integrates high-interrupting breakers and

thermal magnetic safeguards within its internal framework to ensure electrical stability. The user interface features an

intuitive HMI for live tracking of metrics, supported by a specialized marine vfd control board for rapid data processing. To

sustain operational integrity in humid climates, the enclosure is fitted with industrial cooling fans and anti-condensation

heaters. The design further prioritizes safety with redundant E-stop circuits and lightning protection. Every internal module

is secured with specialized dampers to neutralize engine room harmonics, shielding the vessel’s grid from harmonic interference.

Design and Compliance

Design:

Fabricated from 2.0mm 316L stainless steel, the enclosure is synonymous with marine-grade longevity. It utilizes advanced

welding and high-resilience gaskets to lock out moisture, meeting the strict requirements of a customizable hoist control panel.

The interior architecture follows stringent EMC guidelines, employing shielded cabling to protect sensitive navigation arrays from

electromagnetic noise.

Compliance:

Every unit is built to exceed international maritime classifications, aligning with IEC 60529 and IEC 61439 standards for low-voltage

switchgear. As a specialized lifting solution, the hardware undergoes intensive salt-fog and stress tests. Whether deployed as a

custom OEM vfd control board configuration or a turnkey solution, compliance with global safety mandates and environmental

protection protocols remains a core guarantee.

|

|

|

Key Advantages

Elite Environmental Protection

This equipment excels where standard industrial gear fails. Its ruggedized construction ensures that abrasive dust and seawater

ingress cannot damage the internal electronics, significantly extending the service life of the main drive components.

Precision Motion Control

Functioning as a high-precision controller, the system grants operators "micro-inching" capabilities. This allows the hardware to

handle heavy cargo with surgical precision, significantly lowering the mechanical fatigue on crane brakes and drive trains.

Optimized Grid Health

Operating as a smart power control switchboard, the unit features active harmonic mitigation. This prevents the system from

polluting the vessel’s electrical network, safeguarding the operational lifespan of auxiliary bridge electronics.

Scalable Architecture

The internal communication platform supports diverse protocols like Modbus and Ethernet. This adaptability makes the hardware

easy to sync with vessel-wide automation, offering a future-proof investment for modern fleet management.

Parameter

Rated voltage |

380V - 480V AC (50/60Hz) |

User Interface |

Digital HMI with Real-time Diagnostics |

Cabinet Type |

Floor-standing Power Box |

Protection Level |

IP55(customizable) |

Customization |

Available |

Drive Technology |

High-Precision Frequency Modulation |

Enclosure Material |

2.0mm 316L Stainless Steel |

Application Scenarios

Maritime Deck Machinery

The most prominent use for this equipment is managing heavy-lift shipboard cranes. In this setting, the ip55 marine variable

frequency drive system delivers the massive torque needed for container handling while surviving perpetual salt exposure.

This ensures the operator remains in full control during high-seas maneuvers, facilitating safe and efficient cargo transfer

between vessels or to shore.

Offshore Energy Platforms

This unit is perfectly suited for oil and gas rigs where space is at a premium and the atmosphere is chemically aggressive.

Serving as a rugged power hub, it governs critical pumping and supply crane systems. The oem vfd control board can be

fine-tuned for active heave compensation, keeping loads motionless relative to the seabed even as the platform moves with

the swells.

Coastal Port Infrastructure

Beyond vessel decks, the cabinet is ideal for terminal gantry cranes and seaside chemical processing. The enclosure shields

delicate logic controllers from humid, saline air. Its reliability as a power control switchboard guarantees that vital coastal

infrastructure maintains peak uptime with minimal maintenance requirements.

Mining and Industrial Lifts

The durability of the marine vfd control board makes this unit an excellent choice for underground mines or high-dust smelting

plants. The housing provides a dust-tight barrier, while the control interface manages vertical personnel lifts in environments

where system failure is not an option.