102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86 177 0691 9203 [email protected]

Overview

The ABB ACS510 Industrial VFD Control Cabinet provides a comprehensive motor-control solution tailored for modern automation tasks. Built

around the ACS510 variable frequency drive, it ensures accurate speed adjustment, reduced power consumption, and dependable protection

during demanding operations. The integrated Mitsubishi PLC coordinates all control logic, enabling smooth sequencing, real-time feedback, and

flexible programming options. Designed for a broad range of industrial applications, this cabinet acts as a centralized system for managing

motors and peripheral equipment. Its structured layout, intuitive interface, and robust electrical components help users maintain stable workflows,

adapt to process variations, and optimize daily operation. Whether applied in continuous production or fluid-flow systems, it boosts overall control

efficiency and equipment reliability.

Core Components and Features

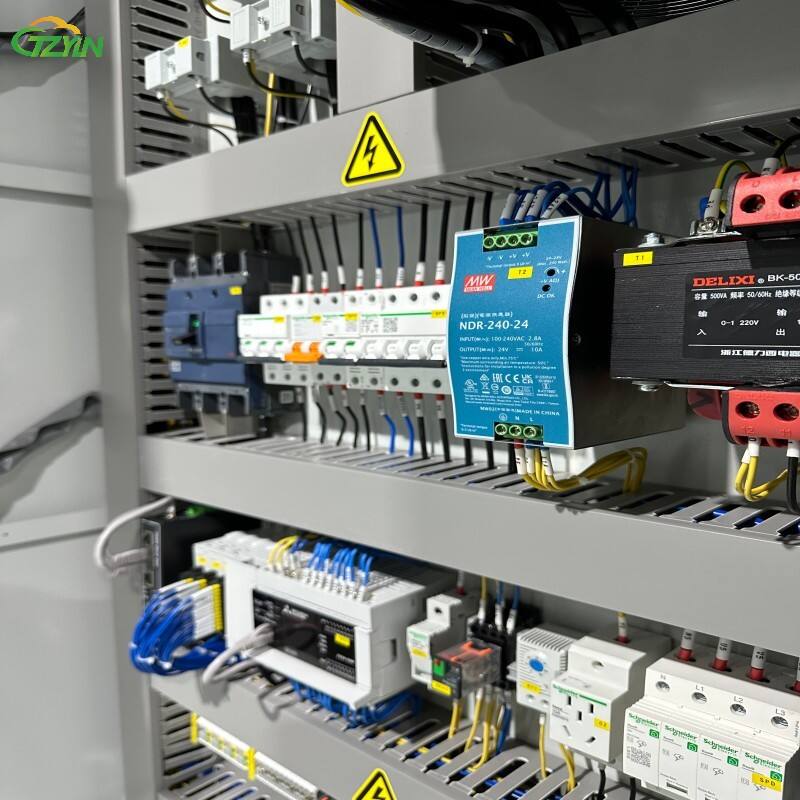

The Core Components and Functions of this control cabinet center around the integration of the ABB ACS510 VFD, Mitsubishi PLC, intuitive control

interface, and robust power-protection modules. The ABB ACS510 operates as the primary drive unit, offering precise frequency and speed regulation

for motors, particularly in fan and pump systems, while providing energy-saving algorithms, multi-level protection, and stable torque output.

Working alongside the VFD, the Mitsubishi PLC manages essential control logic, processes I/O signals, and coordinates communication between devices,

enabling automated sequencing, customized workflow control, and dynamic response to changing system conditions. Operators can interact with the

system through a streamlined control interface that displays speed, frequency, and real-time operating status, while also supporting parameter

configuration, diagnostic evaluation, and smooth switching between manual and automatic modes. Complementing these functions, the power and

protection modules supply reliable voltage distribution and safeguard the system against overcurrent, overvoltage, and short-circuit events, ensuring

long-term operational stability and extended equipment lifespan.

Design and Compliance

Design:

The cabinet structure is engineered for durability and long-term industrial use. Internal components are arranged in a clean, logical layout to simplify

wiring, airflow, and maintenance. The enclosure supports effective heat dissipation through optimized ventilation pathways, ensuring that the VFD

and PLC operate within safe temperature ranges during continuous workloads. Cable routing boards, mounting plates, and terminal blocks are positioned

to enhance accessibility, reduce maintenance time, and facilitate future expansion or reconfiguration. The overall design emphasizes efficiency, stability,

and ease of integration into new or existing automation systems.

Compliance:

Each part of the control cabinet meets established industrial electrical regulations and global standards for performance and safety. The ABB ACS510 drive

and Mitsubishi PLC are certified for international use and comply with guidelines related to electromagnetic compatibility, operational safety, and equipment

reliability. Protective devices and wiring materials follow recognized low-voltage specifications to ensure dependable operation in varied industrial environments.

This compliance foundation guarantees that the cabinet can be confidently deployed across multiple sectors, offering consistent performance while adhering

to regulatory expectations.

|

|

|

Key Advantages

Significant Energy Optimization

The cabinet uses the ABB ACS510’s advanced motor-control algorithms to adjust motor speed precisely according to real-time load demand. By matching

output to system requirements, it significantly reduces energy consumption in fans, pumps, and other variable-flow applications. This targeted regulation

helps lower operating costs while maintaining consistent performance and reducing unnecessary mechanical wear during continuous operation.

Enhanced Automation Capability

With Mitsubishi PLC integration, the system supports complex logic processing, coordinated multi-motor control, and flexible programming. These automation

features reduce manual involvement, improve workflow stability, and ensure that motor-driven processes adapt smoothly to changing industrial conditions.

Quick PLC response enhances reliability and efficiency across automated tasks.

High Reliability and System Protection

Built with dependable power modules and protective devices, the cabinet safeguards equipment against overloads, voltage spikes, and short circuits. This

robust protection framework minimizes downtime, extends component lifespan, and maintains stable operation, even in demanding environments requiring

long-term reliability.

Intuitive Operation and Monitoring

The operator panel provides real-time operating data and supports easy configuration, diagnostics, and mode switching. Its user-friendly layout shortens

technician training time and enables quick adjustments and troubleshooting without specialized expertise, improving overall maintenance efficiency.

Parameter

Voltage Rating |

380V Low Voltage |

VFD Model |

ABB ACS510 |

PLC Model |

Mitsubishi Series |

Protection Level |

IP55(customizable) |

Customization |

Available |

Protection Features |

Overcurrent, Overvoltage, Short-Circuit |

Operating Temperature |

-10°C ~ 50°C |

Application Scenarios

Fluid-Flow and HVAC Systems

The cabinet is highly effective for pumps, fans, and blowers used in HVAC facilities, large commercial air-handling systems, water-treatment stations,

and industrial cooling loops. The ACS510 precisely adjusts motor speed to maintain stable pressure, optimized flow, and balanced system performance.

Its energy-efficient control is especially valuable for equipment that runs continuously, helping reduce long-term power consumption, mechanical stress,

and noise levels. This makes it a reliable solution for facilities that require consistent airflow, water circulation, and temperature regulation.

Manufacturing and Processing Lines

In automated production environments, the cabinet coordinates motors that drive conveyors, mixers, feeders, grinders, and other material-handling

components. The Mitsubishi PLC supports advanced logical sequencing, synchronized multi-motor operation, and rapid response to upstream or

downstream process variations. These capabilities enhance workflow efficiency, minimize bottlenecks, and ensure consistent throughput. The

system’s flexibility also supports recipe-based production, batch processing adjustments, and integration into modern smart-manufacturing platforms.

Industrial Automation and Engineering Projects

As a scalable low-voltage control platform, the cabinet fits applications such as packaging machines, assembly systems, robotic stations, and integrated

automation lines. Its modular design allows additional sensors, actuators, and fieldbus communication modules to be incorporated as project requirements

evolve. This adaptability supports custom engineering solutions and enables seamless integration with supervisory control systems, making it suitable

for both new installations and system upgrades.

Commercial and General Industrial Facilities

Ideal for large buildings, utilities, logistics centers, and factories that rely on dependable and efficient motor control. Its energy-saving performance,

protective features, and stable operating behavior help reduce maintenance workloads, lower operating costs, and extend equipment service life. The

cabinet enhances the overall reliability of daily facility management by preventing unexpected shutdowns and ensuring consistent operation across

various essential building systems.