102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86 177 0691 9203 [email protected]

Overview

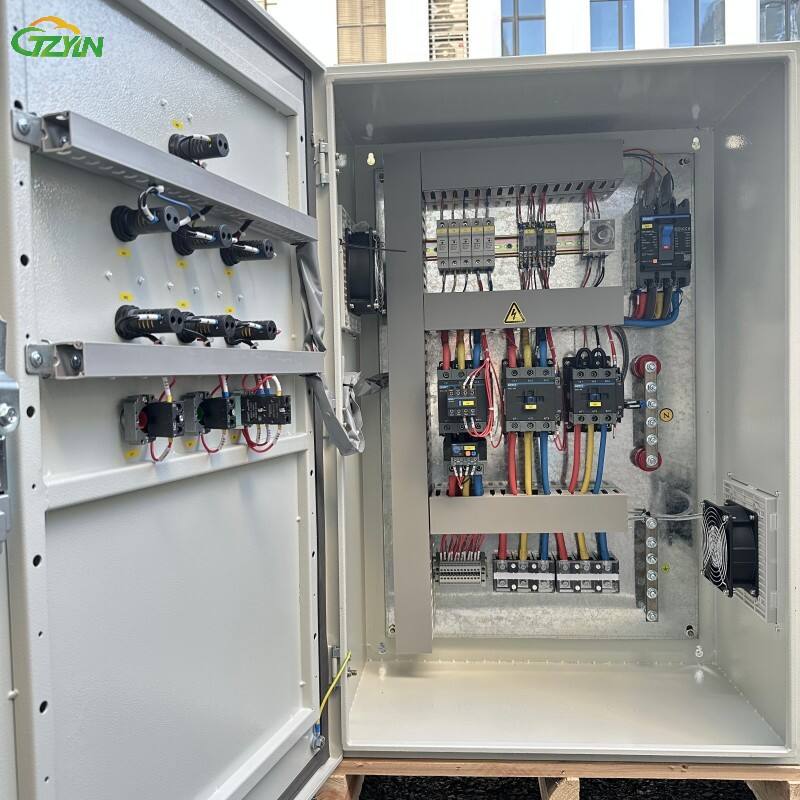

This dedicated motor control solution is expertly engineered to seamlessly complement any existing soft starter system, transforming it

from a mere starting mechanism into a complete and robust motor management unit. Functioning primarily as a Soft Start Delta Transition

box, it precisely manages the high-current switching phases associated with the transition to full-voltage operation. Critically, it provides

robust, reliable circuit protection—including comprehensive overload and short-circuit guarding—that a soft starter alone may lack. The

panel arrives inclusive of all necessary internal components and front-mounted controls for local operational command and crucial status

monitoring. Built as a durable Industrial Electric Control Box, it is designed to optimize the operational lifecycle and energy efficiency

of your demanding High Current Motor Control Panel applications, all while strictly adhering to stringent international safety standards and

operational sequencing protocols.

Core Components and Features

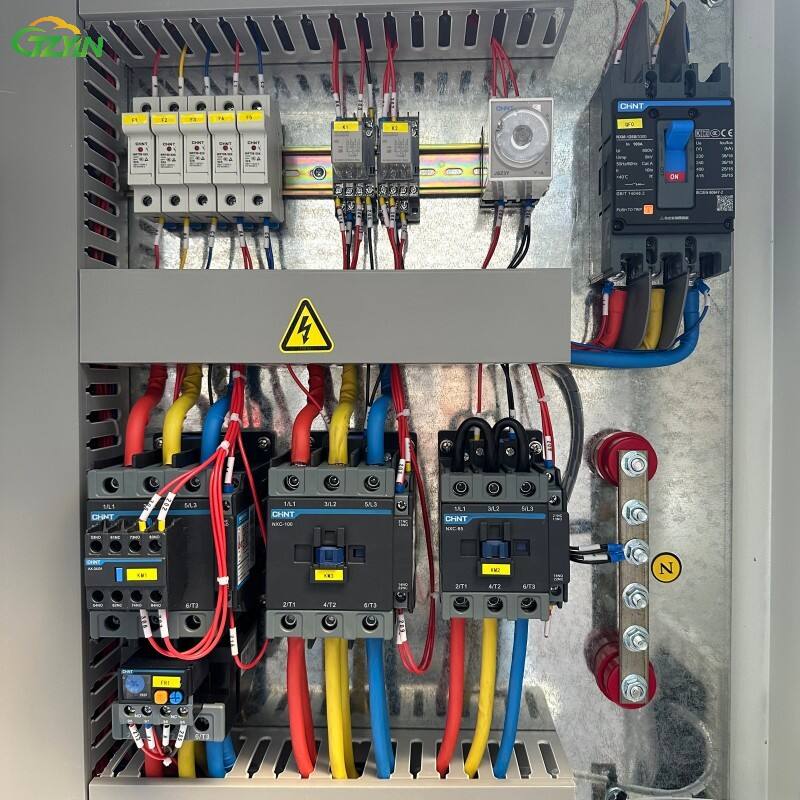

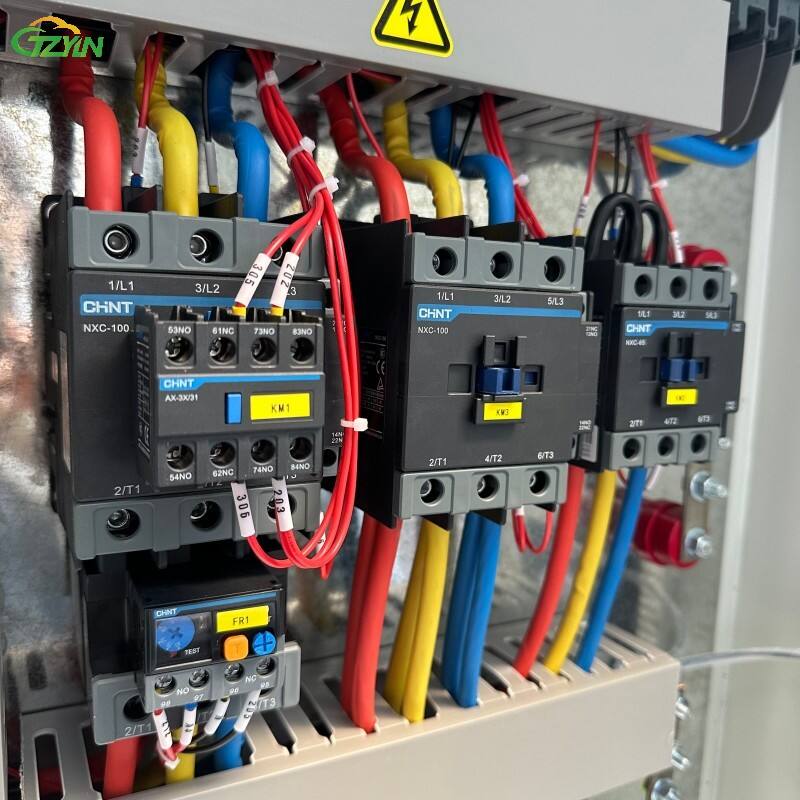

The operational core of this robust Pump Motor Control cabinet is built around industrial-grade power contactors (KM1, KM2, KM3) which

are meticulously configured for the high-current demands of Star-Delta operation. Critical motor safety is assured by a highly reliable

thermal Overload Protection Panel relay (FR1) integrated downstream, safeguarding the motor windings from sustained overcurrent.

Providing the first layer of defense, the integrated Main Circuit Breaker (QFO) delivers essential short-circuit protection and serves as

the primary, lockable power disconnect. Control logic and timing are precisely managed by auxiliary relays (K1, K2) and a dedicated

timing relay (JSZ3Y). This sophisticated arrangement guarantees a precise, sequential, and time-controlled switching sequence from the

initial Star (Wye) configuration to the final Delta running state immediately following the soft start ramp-up. This engineered transition

ensures the motor transitions smoothly and safely, even under the stress of heavy loads. For user interaction, the frontal panel is

equipped with a three-position selector switch (OFF/Manual/Auto), durable Start/Stop pushbuttons, and clear visual indicators (Run, Fault,

Low Water Alarm), culminating in a comprehensive and highly effective local control station.

Design and Compliance

Design:

The enclosure of this 3 Phase Motor Starter board is constructed from heavy-gauge, durable material, offering excellent protection

against industrial environments. It features an efficient internal cooling system, including dual ventilation fans, to dissipate heat and

maintain component integrity, essential for High Current Motor Control Panel applications. Inside, power wiring is clearly color-coded

(Red, Yellow, Blue for phases, Black for control) and neatly routed on DIN rails and busbars. All terminals are clearly marked, facilitating

quick installation and maintenance. The design rigorously separates power and control wiring pathways to minimize electromagnetic

interference (EMI) and enhance operational reliability.

Compliance:

The control box utilizes certified, globally recognized components from reputable manufacturers like CHINT (NXM Breaker, NXC Contactors),

ensuring compliance with international safety and performance standards (e.g., IEC/EN standards). Critical safety features include the

primary disconnect switch and the integrated thermal relay protection, which is vital for preventing motor damage due to sustained overcurrent

or phase loss—a non-negotiable feature for any professional Power control box. Furthermore, the inclusion of a door-mounted earth connection

point emphasizes adherence to grounding regulations for personnel and equipment safety.

|

|

|

Key Advantages

Enhanced Motor Protection and Longevity

The combination of the soft starter's ramp-up capability and this panel’s precise Star-Delta transition minimizes electrical and mechanical

stress on the motor and connected equipment. The integrated thermal Overload Protection Panel and main circuit breaker offer dual-layer

defense against faults, significantly extending the lifespan of your motors and reducing unexpected downtime, making this a reliable 3 phase

control cabinet.

Optimized Energy Management

By facilitating the switch from the high inrush current of a standard Star-Delta start to a smooth, soft-start, followed by an efficient Delta

run, the panel helps reduce peak demand charges and improve power factor during the start sequence. This intelligent power distribution

capability makes it a cost-effective alternative to relying solely on a full-voltage starter.

Streamlined Operation and Maintenance

The fully pre-wired Star Delta Motor Control Panel arrives ready for connection, drastically reducing field installation time and complexity.

Clear labeling, front-mounted indicators (Run, Fault, Alarm), and local Start/Stop controls simplify daily operation and troubleshooting. The

hinged inner panel allows easy access to components, simplifying routine inspection and component replacement.

Parameter

Input Voltage |

3 Phase, 380V - 415V AC |

Operation Mode |

OFF / Manual / Auto (External PLC/Remote Signal) |

Starter Type |

Star-Delta (Wye-Delta) Transition |

Protection Level |

IP54(customizable) |

Customization |

Available |

Frequency |

50Hz / 60Hz |

Protection |

Short-Circuit (MCB/MCCB), Thermal Overload (FR) |

Application Scenarios

Pumping Stations and Water Treatment

This robust Pump Motor Control cabinet is ideally suited for constant and variable pressure pumping systems, including municipal water

supply, sewage treatment, and irrigation facilities. In these applications, the Soft Start Delta Transition box ensures the pump starts smoothly,

preventing water hammer effects that can damage pipes and mechanical seals. The Low Water Alarm indicator and safety interlocks facilitate

autonomous operation and protection, making it a reliable component for critical water infrastructure.

HVAC and Large Ventilation Systems

For large commercial and industrial heating, ventilation, and air conditioning (HVAC) systems, the panel manages high-inertia loads such as

large fan motors and centrifugal chillers. Utilizing the soft start and Star-Delta transition reduces the mechanical strain on belts, couplings, and

ducts, while the integrated Overload Protection Panel guards against motor burnout during continuous operation under fluctuating air resistance.

Conveying and Material Handling Systems

In demanding material handling operations, such as conveyors, crushers, and mixers, the panel's ability to handle high starting currents is

crucial. The controlled acceleration provided by the Soft Starter Bypass Panel functionality prevents jerking, spilled materials, and mechanical

shock that can lead to premature equipment failure. This is especially vital in mining, aggregate processing, and manufacturing where downtime

is costly.

General Industrial Machinery

The High Current Motor Control Panel can be deployed across various industrial machines, including lathes, presses, and specialized manufacturing

equipment. Any application utilizing a large 3-phase induction motor, particularly those requiring reduced inrush current and reliable, consistent

starting torque, benefits from the panel's integrated protection and precise switching capabilities, making it a universal 3 phase control cabinet solution.