102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86 177 0691 9203 [email protected]

Overview

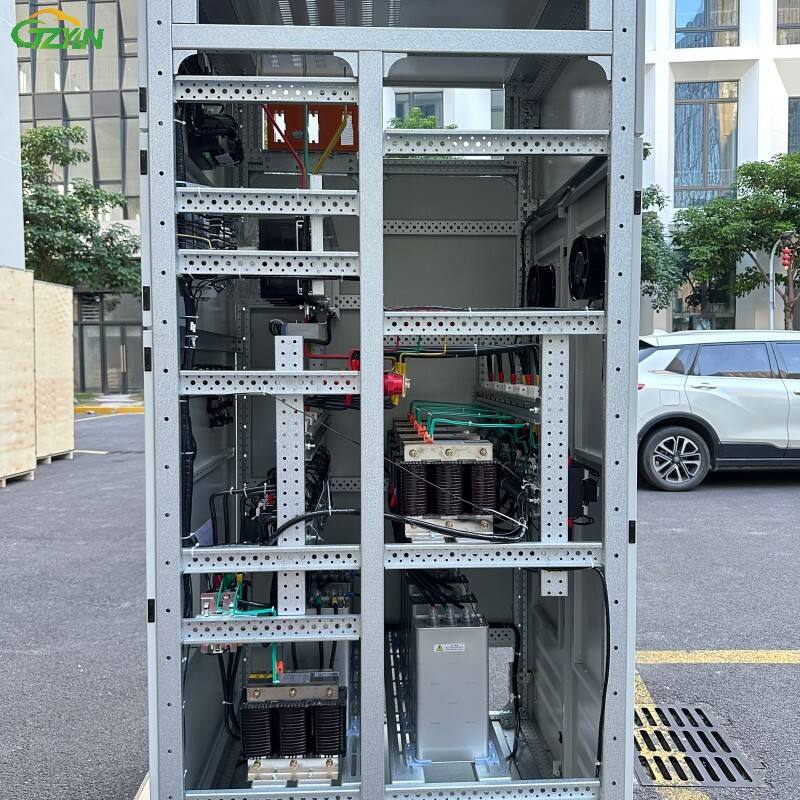

Capacitor compensation cabinets, often referred to as power correction cabinets or industrial capacitor banks, are essential components

in modern electrical systems. As power compensation control cabinets and electrical power compensation units, they effectively resolve

reactive power issues and improve power factor. When integrated with distribution boards and electrical switch boxes, these systems

stabilize voltage, lower energy costs, and safeguard equipment. Acting as reliable electrical control panels, they are indispensable in

industrial environments, ensuring efficient energy use and smooth operations in factories, processing plants, and large-scale facilities

seeking dependable power management solutions.

Core Components and Features

A capacitor compensation cabinet, functioning as an electrical power compensation unit, is composed of capacitors, contactors,

reactors, and intelligent controllers. Capacitors store and release reactive power, improving power factor and lowering electricity

expenses. Contactors manage switching between capacitor banks, ensuring smooth operation, while reactors help suppress

harmonic distortion for cleaner power delivery.

Equipped with sensors and an intelligent control system, the cabinet monitors real-time power demand and adjusts output accordingly. The

industrial capacitor bank automatically adapts to load variations, maintaining efficiency under changing conditions. Integrated with distribution

boards and electrical switch boxes, this power correction cabinet stabilizes system voltage, prevents overheating of electrical equipment,

and extends the service life of industrial machinery.

By functioning as both a power compensation control cabinet and an electrical control panel, it guarantees reliable and efficient operation,

making it a vital solution for industries requiring stable and optimized power usage.

Design and Compliance

Design:

The capacitor compensation cabinet features a durable enclosure designed to resist dust, moisture, and temperature fluctuations. Its

compact layout ensures simple installation in space-constrained environments, while the intuitive interface allows for straightforward

operation and maintenance. Compatible with distribution boards and electrical switch boxes, it offers reliable performance in demanding i

ndustrial conditions.

Compliance:

All models, including the industrial capacitor bank and power correction cabinet, meet international safety and performance standards

such as IEC and UL. The electrical power compensation unit complies with energy efficiency regulations and electrical equipment safety

codes. This ensures global applicability, reduces operational risks, and guarantees dependable integration with existing distribution boards

and electrical switch systems.

|

|

|

Key Advantages

Enhanced Energy Efficiency:

Optimizes power factor precisely, cuts reactive power losses in industrial operations, eases grid burden, and slashes electricity

costs—critical for high-consumption factories to reduce long-term operational expenses.

Automatic Operation:

Uses intelligent modules to monitor load changes in real time, adjusts internal components like capacitor banks automatically,

avoids manual intervention, and maintains stable performance even during peak production, preventing human-error disruptions.

Industrial Durability:

Built with rugged, corrosion-resistant enclosures and quality parts, endures dust, moisture, and temperature swings in harsh

industrial settings, lowers failure risks, reduces unplanned downtime and maintenance frequency, saving time and labor.

Seamless Integration:

Has standardized interfaces, connects easily to existing distribution boards and electrical switch boxes, needs no major system

modifications, and boosts overall power network reliability and stability for smooth component coordination.

Parameter

| Voltage Range | 380V - 10kV (customizable) |

| Capacitance Capacity | 10kvar - 1000kvar (per cabinet) |

| Operating Temperature | -25°C to +45°C |

| Protection Class | IP40 - IP54 (optional) |

| Control Mode | Automatic/Manual |

Application Scenarios

Manufacturing Facilities:

Stabilizes power for heavy machinery, preventing voltage drops that may affect production lines. Widely used in automotive,

electronics, and precision equipment factories, it works alongside distribution boards and electrical switch boxes to ensure

continuous production.

Commercial Buildings:

Enhances energy efficiency in malls, office complexes, and hotels. By integrating with distribution boards, it reduces operating

costs and ensures reliable operation of HVAC, elevators, and lighting systems.

Data Centers:

Provides stable power for servers and networking equipment, reducing fluctuations that threaten data security. When combined

with electrical switch boxes, it ensures uninterrupted performance of critical IT infrastructure.

Renewable Energy Plants:

Optimizes variable output from solar and wind sources. The power correction cabinet and industrial capacitor bank balance load

fluctuations, improving grid stability and supporting reliable integration of renewable energy into existing electrical systems.