How GCK Cabinets Optimize Power Management and Safety

GCK Cabinets have established themselves as a reliable solution in low-voltage power distribution systems, widely used in industrial plants, commercial buildings, and infrastructure projects. Designed as withdrawable switchgear cabinets, they combine smart engineering with practical features to enhance both power management efficiency and electrical safety. In environments where consistent power supply and protection against hazards are critical, GCK Cabinets deliver targeted solutions that address the unique challenges of modern power systems. This guide explains how GCK Cabinets optimize power management and safety, highlighting their key features and real-world applications.

Streamlined Power Distribution for Efficient Management

Effective power management begins with a distribution system that minimizes energy loss, balances loads, and ensures stable supply to critical equipment. GCK Cabinets are engineered to streamline this process through their structured design and functional components.

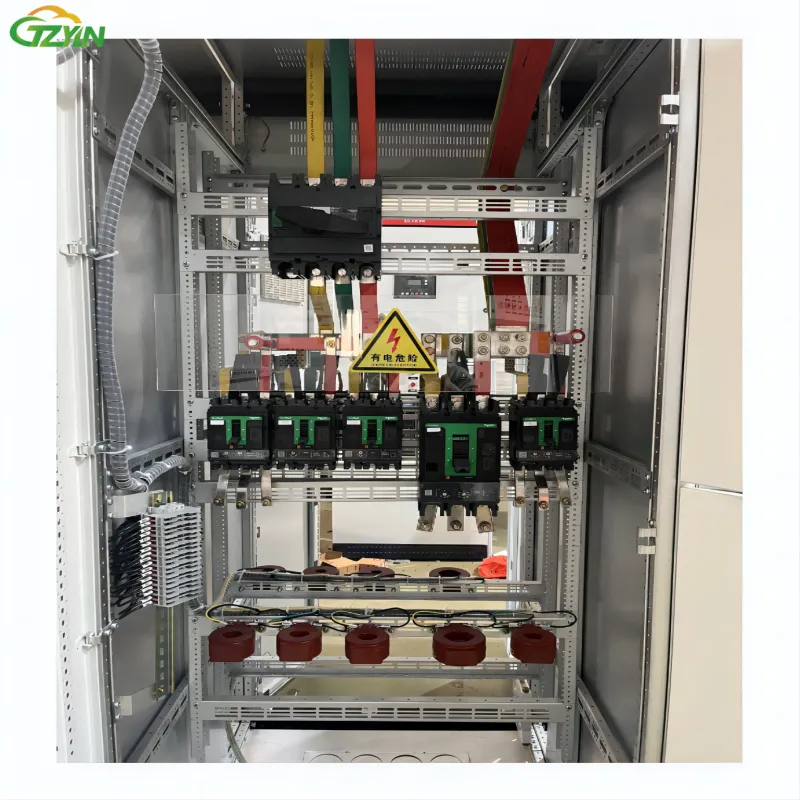

At the core of GCK Cabinets is a withdrawable module system, where key components like circuit breakers, contactors, and relays are housed in removable drawers. This design allows for precise control over power distribution, as each module can be dedicated to specific circuits or equipment. For example, in a manufacturing plant, separate modules can manage power for production lines, lighting, and HVAC systems, making it easy to monitor and adjust energy flow to each area. This targeted distribution reduces energy waste by preventing overloading of circuits and ensuring power is allocated where it is most needed.

GCK Cabinets also feature low-resistance busbars made from high-conductivity materials like copper or aluminum. These busbars minimize energy loss through heat dissipation, a common issue in traditional distribution systems that can increase operational costs. The busbar layout is optimized for efficient current flow, with clear pathways that reduce voltage drops even in high-load scenarios. This stability is crucial for sensitive equipment in commercial settings, such as servers in data centers or medical devices in hospitals, where voltage fluctuations can cause malfunctions or data loss.

Additionally, GCK Cabinets integrate with energy monitoring tools, allowing facility managers to track power usage in real time. By analyzing data on energy consumption, load distribution, and peak usage times, managers can identify inefficiencies and adjust operations to reduce waste. This data-driven approach to power management helps industrial and commercial facilities lower energy bills while maintaining reliable performance.

Flexible Configuration for Adapting to Changing Needs

Power requirements in industrial and commercial settings are rarely static. Expansions, equipment upgrades, or new technologies often demand adjustments to the electrical system. GCK Cabinets address this with a flexible, modular design that allows for easy reconfiguration without major overhauls.

The withdrawable modules in GCK Cabinets can be quickly added, removed, or replaced to accommodate changing power needs. For instance, if a commercial building adds new office spaces with increased lighting and HVAC demands, additional circuit breaker modules can be inserted into the cabinet to handle the extra load. This eliminates the need to replace the entire cabinet or rewire the system, saving time and reducing downtime. In industrial plants, where production lines may be modified or new machinery installed, swapping out modules ensures the power distribution system can adapt without disrupting operations.

GCK Cabinets also support standardized module sizes and interfaces, ensuring compatibility with components from different manufacturers. This interchangeability simplifies inventory management, as spare parts can be sourced from multiple suppliers, and reduces the need for specialized training for maintenance teams. Whether scaling up for growth or modifying systems to support renewable energy sources like solar panels, the flexibility of GCK Cabinets makes them a long-term solution that grows with the facility.

Advanced Safety Features to Protect Personnel and Equipment

Electrical safety is a top priority in any facility, and GCK Cabinets are designed with multiple layers of protection to prevent accidents, equipment damage, and downtime. These safety features address common hazards like arc flashes, short circuits, and unauthorized access to live components.

One key safety feature is the door interlock system, which prevents doors from being opened when the cabinet is energized. This ensures that maintenance workers can only access internal components after the power has been safely disconnected, reducing the risk of electric shock. The interlocks are mechanical or electronic, with clear indicators showing whether the cabinet is live or de-energized, leaving no room for confusion during maintenance procedures.

GCK Cabinets also include arc-resistant designs that contain and redirect arc flashes—a dangerous release of energy caused by electrical faults. Arc flashes can reach extremely high temperatures and pressure, posing risks to personnel and equipment. The cabinet’s robust construction, including reinforced panels and arc containment barriers, limits the spread of arc flashes to individual modules, preventing widespread damage. Ventilation systems are strategically placed to direct hot gases and pressure away from operators, further enhancing safety during fault conditions.

To prevent overloads and short circuits, GCK Cabinets are equipped with protective devices like circuit breakers and fuses that automatically disconnect power when abnormal conditions are detected. These devices are calibrated to trip quickly, minimizing the duration of the fault and reducing the risk of fire or equipment damage. In industrial settings with heavy machinery, this rapid response is critical for preventing costly breakdowns and ensuring worker safety.

Additionally, GCK Cabinets are built with insulation materials that meet strict international standards, preventing leakage currents and reducing the risk of ground faults. All components are tested for durability and performance under extreme conditions, ensuring they can withstand the demands of industrial environments without compromising safety.

Easy Maintenance for Reducing Downtime

Regular maintenance is essential for keeping power distribution systems running smoothly, but it can be disruptive if not managed efficiently. GCK Cabinets are designed to simplify maintenance procedures, reducing downtime and ensuring that systems are back online quickly.

The withdrawable modules in GCK Cabinets allow for easy access to components without shutting down the entire system. If a circuit breaker or contactor needs repair or replacement, the module can be withdrawn while other parts of the cabinet remain operational. This “hot swapping” capability is invaluable in critical facilities like hospitals or data centers, where even brief downtime can have serious consequences. Maintenance teams can work on one module at a time, minimizing disruption to overall operations.

GCK Cabinets also feature clear labeling and documentation, with diagrams and markings that guide technicians through inspection and repair processes. This reduces the time spent diagnosing issues and ensures that maintenance tasks are performed correctly. Removable panels and easy-to-reach components further simplify access, allowing technicians to complete tasks quickly and safely.

Routine maintenance, such as cleaning, tightening connections, or testing protective devices, is streamlined with features like tool-free access points and modular components that can be inspected without disassembly. This proactive approach to maintenance helps prevent unexpected failures, extending the lifespan of the cabinet and reducing long-term costs.

Durability for Long-Term Reliability in Harsh Environments

Industrial and commercial facilities often expose electrical equipment to harsh conditions, including dust, moisture, vibration, and extreme temperatures. GCK Cabinets are built to withstand these challenges, ensuring long-term reliability and reducing the need for frequent replacements.

Constructed from high-quality materials like galvanized steel, GCK Cabinets resist corrosion and physical damage, even in industrial environments with high levels of dust or chemicals. Sealed gaskets and IP-rated enclosures protect internal components from moisture ingress, making them suitable for use in outdoor settings or facilities with high humidity, such as food processing plants or wastewater treatment facilities.

Vibration resistance is another key feature, with reinforced mounting points and shock-absorbing materials that prevent components from loosening or failing in facilities with heavy machinery. This durability ensures that GCK Cabinets maintain performance in environments where traditional cabinets might degrade over time.

GCK Cabinets also undergo rigorous testing to ensure they can operate in extreme temperatures, from freezing conditions in cold storage facilities to high heat in manufacturing plants. This wide operating range makes them versatile enough for use in diverse climates and settings, providing consistent power management and safety regardless of environmental challenges.

FAQ

What does GCK stand for in GCK Cabinets?

GCK is an abbreviation for Withdrawable Switchgear Cabinet in Chinese, referring to the cabinet’s design with removable modules for easy maintenance and reconfiguration.

What types of facilities benefit most from GCK Cabinets?

GCK Cabinets are widely used in industrial plants (manufacturing, mining, oil and gas), commercial buildings (hospitals, shopping malls, offices), data centers, and infrastructure projects requiring flexible and safe power distribution.

How do GCK Cabinets improve energy efficiency?

They reduce energy loss through optimized busbar designs, minimize voltage drops, and integrate with monitoring tools to track usage, allowing facilities to identify and reduce waste.

Are GCK Cabinets suitable for outdoor use?

Yes, many GCK Cabinets have IP65 or higher weatherproof ratings, protecting against dust and water ingress, making them suitable for outdoor applications like construction sites or outdoor electrical substations.

How often should GCK Cabinets be maintained?

Routine maintenance, including inspections and component checks, is recommended every 6–12 months. Their modular design makes maintenance quick and minimizes downtime.