Key Advantages of MNS Cabinets in Industrial and Commercial Applications

MNS Cabinets have become a cornerstone in modern electrical distribution systems, trusted in industrial plants, commercial buildings, data centers, and critical facilities worldwide. Designed as modular low-voltage switchgear, these cabinets offer a blend of flexibility, safety, and efficiency that traditional electrical enclosures struggle to match. Whether managing power distribution, protecting sensitive equipment, or adapting to changing operational needs, MNS Cabinets deliver consistent performance in diverse environments. This guide explores the key advantages that make MNS Cabinets indispensable in industrial and commercial applications.

Modular Design for Flexible Configuration

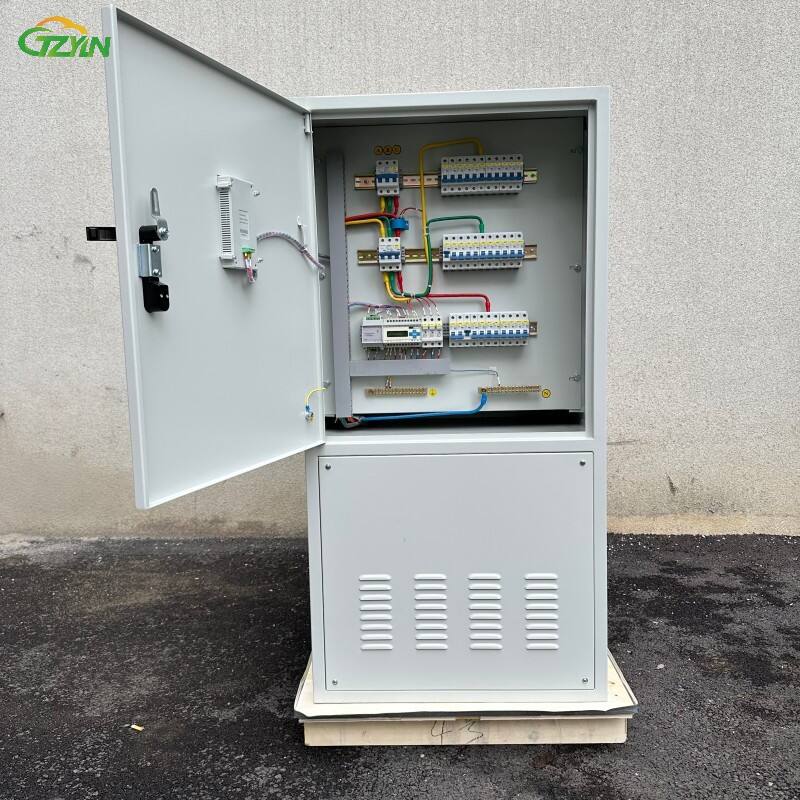

One of the most significant advantages of MNS Cabinets is their modular design, which allows for easy customization and adaptation to evolving electrical needs. Unlike fixed traditional cabinets that require complete replacement when system requirements change, MNS Cabinets are built with interchangeable components—such as switch modules, circuit breakers, and busbars—that can be added, removed, or reconfigured without overhauling the entire system.

This modularity is particularly valuable in industrial settings, where production lines may expand, or machinery may be upgraded, increasing power demands. For example, a manufacturing plant adding new equipment can simply integrate additional circuit breakers or busbar sections into existing MNS Cabinets, avoiding costly downtime and infrastructure changes. In commercial buildings like shopping malls or offices, modularity allows for easy updates to lighting, HVAC, or security systems by reconfiguring the electrical distribution layout within the cabinets.

MNS Cabinets also support standardized module sizes, ensuring compatibility across different components and brands. This standardization simplifies inventory management, as spare parts can be stocked universally, and reduces installation time, as modules fit seamlessly into pre-designed slots. Whether scaling up for growth or modifying systems for new technologies, the modular design of MNS Cabinets provides unmatched flexibility.

Enhanced Safety Features for Electrical Protection

Electrical safety is paramount in industrial and commercial environments, where the risk of short circuits, overloads, or arc flashes can lead to equipment damage, downtime, or even accidents. MNS Cabinets are engineered with robust safety features that minimize these risks, protecting both personnel and assets.

First, MNS Cabinets include built-in isolation and separation barriers that prevent electrical arcs from spreading between components. This arc-resistant design contains faults within individual modules, reducing the risk of fire or injury during a malfunction. Additionally, doors and panels are equipped with interlocks that prevent access to live parts when the cabinet is energized, ensuring maintenance workers can only perform tasks when the system is safely deactivated.

Thermal management is another critical safety aspect. MNS Cabinets feature ventilation systems and heat-dissipating components that prevent overheating, even in high-load industrial environments. This reduces the risk of insulation degradation or component failure due to excessive temperatures. For sensitive applications like data centers, where consistent cooling is essential, MNS Cabinets can integrate with building HVAC systems to maintain optimal operating temperatures for electrical equipment.

Compliance with international safety standards—such as IEC, UL, and local electrical codes—further reinforces their reliability. MNS Cabinets undergo rigorous testing to ensure they meet strict criteria for fault tolerance, insulation, and protective grounding, giving facility managers confidence in their ability to handle electrical hazards.

High Efficiency in Power Distribution

MNS Cabinets optimize power distribution efficiency, reducing energy losses and ensuring stable electricity flow to critical equipment. Their design minimizes resistance in busbars and connections, where energy waste often occurs in traditional systems. Low-resistance copper or aluminum busbars with precision-engineered joints ensure maximum conductivity, reducing heat generation and energy dissipation.

In industrial applications, where large motors, pumps, and machinery demand consistent power, this efficiency translates to lower operational costs. For example, a factory relying on MNS Cabinets for power distribution will experience fewer voltage drops, ensuring machinery operates at peak performance and reducing energy bills over time. In commercial buildings, efficient power distribution supports energy management systems, allowing for better control over lighting, HVAC, and other utilities, which is key for meeting sustainability goals.

MNS Cabinets also integrate seamlessly with smart monitoring systems, enabling real-time tracking of power usage, load distribution, and energy consumption. This data helps facility managers identify inefficiencies, balance loads across phases, and optimize power allocation, further enhancing overall system efficiency. Whether in a high-power industrial plant or a energy-conscious commercial building, MNS Cabinets deliver reliable, efficient power distribution.

Easy Installation and Maintenance

Installing and maintaining electrical switchgear can be time-consuming and costly, especially in large facilities. MNS Cabinets streamline these processes with user-friendly features that reduce downtime and labor requirements.

During installation, the modular design allows for quick assembly, as prefabricated modules are simply connected to the main busbar system. This eliminates the need for complex on-site wiring and reduces the risk of installation errors. In commercial buildings with limited space, such as high-rise offices, MNS Cabinets’ compact design and standardized dimensions make them easy to fit into tight electrical rooms or utility closets.

Maintenance is equally simplified. MNS Cabinets provide clear access to components through removable panels and doors, allowing technicians to inspect, test, or replace parts without disconnecting the entire system. Modular components can be pulled out or swapped in minutes, minimizing downtime during repairs. For example, a faulty circuit breaker in an industrial MNS Cabinet can be replaced with a new module while other parts of the system remain operational, ensuring continuous power to critical machinery.

The cabinets also feature labeling and documentation systems that simplify troubleshooting. Clear marking of circuits, components, and wiring diagrams helps technicians quickly identify issues, reducing diagnostic time and improving maintenance accuracy. In busy commercial facilities like hospitals or airports, where downtime is unacceptable, these maintenance-friendly features are invaluable.

Durability and Longevity in Harsh Environments

Industrial and commercial environments often expose electrical equipment to harsh conditions, including dust, moisture, vibration, and temperature fluctuations. MNS Cabinets are built to withstand these challenges, ensuring long-term reliability and reducing the need for frequent replacements.

Constructed from high-quality materials like galvanized steel or aluminum, MNS Cabinets resist corrosion and physical damage. Sealed gaskets and IP-rated enclosures protect internal components from dust ingress in factories or moisture in outdoor commercial settings, such as parking garages or wastewater treatment plants. In industrial plants with heavy machinery, vibration-dampening mounts prevent component loosening or wear, maintaining system integrity over time.

MNS Cabinets also undergo rigorous testing for environmental resistance, ensuring they perform reliably in extreme temperatures—from freezing cold in food processing facilities to high heat in foundries. This durability extends their lifespan, often exceeding 20 years with minimal maintenance, making them a cost-effective investment for long-term operations.

For facilities in coastal areas or industrial zones with high pollution levels, optional coatings and treatments further enhance corrosion resistance, ensuring the cabinets remain functional and safe for decades.

Compatibility with Smart Grid and Digital Systems

As industrial and commercial facilities adopt smart technologies, MNS Cabinets seamlessly integrate with digital systems, supporting modern power management and automation. These cabinets are designed to connect with sensors, meters, and control systems that monitor electrical parameters like voltage, current, and power quality in real time.

In smart factories, MNS Cabinets feed data to industrial control systems (ICS) or SCADA (Supervisory Control and Data Acquisition) platforms, enabling remote monitoring and predictive maintenance. For example, a sudden spike in current detected by sensors in the cabinet can trigger alerts, allowing technicians to address potential issues before they cause failures. In commercial buildings, integration with building management systems (BMS) allows for centralized control of power distribution, optimizing energy usage based on occupancy or time of day.

MNS Cabinets also support communication protocols like Modbus, Profibus, or Ethernet/IP, ensuring compatibility with a wide range of digital tools and IoT devices. This connectivity future-proofs electrical systems, allowing facilities to adopt new technologies—such as renewable energy integration or energy storage—without replacing the entire cabinet infrastructure. Whether in a digitalized industrial plant or a smart commercial building, MNS Cabinets serve as a hub for efficient, data-driven power management.

FAQ

What does MNS stand for in MNS Cabinets?

MNS stands for “Modular Niederspannungs-Schaltanlagen,” a German term meaning “Modular Low-Voltage Switchgear.” It refers to the cabinet’s modular design for low-voltage electrical distribution.

What types of industries benefit most from MNS Cabinets?

MNS Cabinets are widely used in industrial sectors (manufacturing, oil and gas, mining), commercial buildings (hospitals, malls, offices), data centers, and critical facilities requiring reliable power distribution.

How do MNS Cabinets differ from traditional electrical cabinets?

Unlike fixed traditional cabinets, MNS Cabinets have a modular design with interchangeable components, offering greater flexibility, easier maintenance, and adaptability to changing power needs.

Are MNS Cabinets suitable for outdoor applications?

Yes, many MNS Cabinets are available with weatherproof enclosures (IP65 or higher) that resist moisture, dust, and temperature extremes, making them suitable for outdoor use.

How often do MNS Cabinets require maintenance?

Routine maintenance (inspections, cleaning, and component checks) is recommended every 6–12 months, depending on the environment. Their modular design makes repairs and part replacements quick and minimally disruptive.