GCS Cabinets: Enhancing Power Distribution with Modular Design Solutions

GCS Cabinets have become a go-to choice for modern power distribution systems in industrial, commercial, and infrastructure settings. As modular low-voltage switchgear, they are engineered to address the growing demand for flexible, efficient, and safe electrical management. Unlike traditional fixed cabinets that limit adaptability, GCS Cabinets use a modular design to simplify installation, maintenance, and upgrades—all while ensuring reliable power flow to critical equipment. This guide explores how GCS Cabinets enhance power distribution through their modular design, highlighting key benefits, applications, and features that make them indispensable in today’s electrical systems.

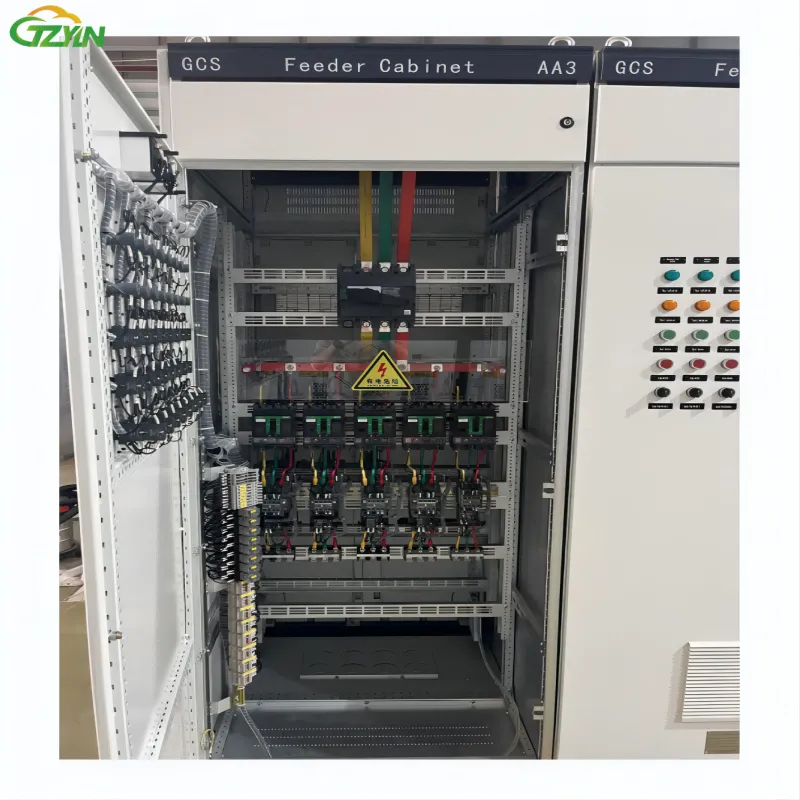

The Basics of GCS Cabinets: Modular Design Explained

At the core of GCS Cabinets is a modular structure that breaks down power distribution into interchangeable components. These cabinets consist of standardized modules, such as withdrawable circuit breaker units, busbar systems, and control compartments, all designed to fit together seamlessly. This modular approach contrasts with traditional fixed cabinets, where components are permanently wired and difficult to modify.

Each module in a GCS Cabinet is self-contained, meaning it can be installed, removed, or replaced without disrupting the entire system. For example, a circuit breaker module can be withdrawn for maintenance while other modules continue supplying power to critical equipment. This design not only reduces downtime but also allows for easy scaling as power needs change. Whether adding new circuits for expanded operations or upgrading to higher-capacity components, GCS Cabinets adapt without requiring a complete system overhaul.

The modularity of GCS Cabinets also extends to their physical layout. They can be configured in various sizes and arrangements to fit specific space constraints, from compact electrical rooms in commercial buildings to large industrial facilities. This flexibility makes them suitable for diverse applications, ensuring optimal use of available space while maintaining efficient power distribution.

Enhanced Power Distribution Efficiency

Efficiency is a key priority in power distribution, and GCS Cabinets are designed to minimize energy loss, balance loads, and ensure stable power flow. Their modular design plays a critical role in achieving these goals by optimizing how electricity is managed and distributed.

GCS Cabinets feature low-resistance busbar systems made from high-conductivity materials like copper or aluminum. These busbars are precision-engineered to reduce energy loss through heat dissipation, a common issue in traditional systems that wastes energy and increases operational costs. The busbar layout is organized to create clear, direct pathways for current, minimizing voltage drops even when handling high loads. This stability is essential for sensitive equipment in settings like data centers, where voltage fluctuations can damage servers or cause data loss, and in industrial plants, where machinery relies on consistent power to operate efficiently.

The modular structure also allows for targeted power distribution. Different modules can be dedicated to specific circuits, such as lighting, HVAC, or machinery, making it easier to monitor and adjust energy flow. For example, in a manufacturing plant, a module supplying power to a production line can be optimized for high loads, while another module managing office lighting can operate at lower capacity. This targeted approach reduces energy waste by ensuring power is allocated exactly where it is needed, improving overall system efficiency.

Additionally, GCS Cabinets integrate with energy monitoring tools that track usage patterns, load distribution, and peak demand. This data helps facility managers identify inefficiencies, adjust operations to reduce waste, and plan for future power needs. By combining modular design with smart monitoring, GCS Cabinets create a more efficient, cost-effective power distribution system.

Flexibility to Adapt to Changing Needs

Power requirements in industrial and commercial facilities are rarely static. Expansions, equipment upgrades, new technologies, or regulatory changes often demand adjustments to electrical systems. GCS Cabinets excel in this dynamic environment, offering the flexibility to adapt without major disruptions.

The withdrawable modules in GCS Cabinets make reconfiguration simple. Adding a new circuit for expanded office space, upgrading to a higher-capacity circuit breaker, or integrating renewable energy sources like solar panels can be done by swapping out modules rather than replacing the entire cabinet. This not only saves time and money but also reduces downtime, a critical advantage in facilities where even brief power interruptions can be costly.

For example, a commercial building adding electric vehicle charging stations can integrate new modules into existing GCS Cabinets to handle the increased load, avoiding the need for extensive rewiring or cabinet replacement. In an industrial plant adopting new machinery, modules can be upgraded to support higher voltages without disrupting production. This adaptability ensures that GCS Cabinets remain functional and relevant as a facility’s needs evolve over time.

Standardization is another key aspect of their flexibility. GCS Cabinets use standardized module sizes and interfaces, ensuring compatibility with components from different manufacturers. This interchangeability simplifies inventory management, as spare parts can be sourced from multiple suppliers, and reduces the need for specialized training for maintenance teams. Whether scaling up for growth or adapting to new technologies, GCS Cabinets provide a flexible solution that grows with the facility.

Improved Safety for Personnel and Equipment

Electrical safety is paramount in any facility, and GCS Cabinets are designed with multiple layers of protection to prevent accidents, equipment damage, and downtime. Their modular design enhances safety by isolating components, limiting hazards, and simplifying safe maintenance.

One critical safety feature is the interlock system, which prevents access to live components when the cabinet is energized. Doors and panels are equipped with mechanical or electronic interlocks that only allow access after the power to a module has been safely disconnected. This ensures that maintenance workers can perform tasks without risk of electric shock, a significant improvement over traditional cabinets where live components may be exposed during repairs.

GCS Cabinets also include arc-resistant designs to contain and mitigate arc flashes—dangerous electrical faults that release high temperatures and pressure. The modular structure limits arc flashes to individual modules, preventing them from spreading to other parts of the system. Reinforced panels, arc containment barriers, and strategic ventilation systems redirect hot gases and pressure away from personnel, reducing the risk of injury or equipment damage during a fault.

Protective devices like circuit breakers and fuses are integrated into each module, providing localized protection against overloads and short circuits. These devices trip quickly to disconnect power when abnormal conditions are detected, minimizing the duration of the fault and preventing further damage. In industrial settings with heavy machinery, this rapid response is crucial for avoiding costly breakdowns and ensuring worker safety.

GCS Cabinets also meet strict international safety standards, such as IEC and UL, which set criteria for insulation, grounding, and fault tolerance. Rigorous testing ensures that they can withstand harsh conditions and operate safely in diverse environments, giving facility managers confidence in their reliability.

Simplified Installation and Maintenance

Installing and maintaining power distribution systems can be complex and time-consuming, but GCS Cabinets are designed to streamline these processes, reducing downtime and labor costs.

Installation is simplified by their modular design. Prefabricated modules are delivered ready to install, with minimal on-site wiring required. Technicians can connect modules to the main busbar system quickly, reducing installation time compared to traditional cabinets, which require extensive wiring and assembly. This is particularly advantageous in large facilities or projects with tight deadlines, where faster installation translates to earlier operational readiness.

Maintenance is equally straightforward. The withdrawable modules allow technicians to access components without shutting down the entire system. A faulty circuit breaker or contactor can be withdrawn, repaired, or replaced while other modules continue supplying power, minimizing downtime. This “hot swapping” capability is invaluable in critical facilities like hospitals, where uninterrupted power is essential for patient care, and in data centers, where even brief outages can disrupt services.

GCS Cabinets also feature clear labeling, diagrams, and tool-free access points that simplify maintenance tasks. Technicians can quickly identify modules, diagnose issues, and perform repairs without specialized training or equipment. Routine maintenance, such as cleaning, testing protective devices, or tightening connections, is made easier by the cabinet’s organized layout and accessible components. This proactive approach to maintenance helps prevent unexpected failures, extending the lifespan of the system and reducing long-term costs.

Durability for Long-Term Reliability

Industrial and commercial environments often expose electrical equipment to harsh conditions, including dust, moisture, vibration, and extreme temperatures. GCS Cabinets are built to withstand these challenges, ensuring long-term reliability and performance.

Constructed from high-quality materials like galvanized steel, GCS Cabinets resist corrosion and physical damage, even in industrial settings with high levels of dust, chemicals, or humidity. Sealed gaskets and IP-rated enclosures protect internal components from moisture ingress, making them suitable for outdoor applications or facilities like food processing plants and wastewater treatment centers, where exposure to water is common.

Vibration resistance is another key feature. GCS Cabinets are equipped with reinforced mounting points and shock-absorbing materials that prevent components from loosening or failing in facilities with heavy machinery or frequent movement. This durability ensures that the cabinets maintain performance in environments where traditional systems might degrade over time.

They also undergo rigorous testing to ensure they can operate in extreme temperatures, from freezing conditions in cold storage facilities to high heat in manufacturing plants. This wide operating range makes GCS Cabinets versatile enough for use in diverse climates and settings, providing reliable power distribution regardless of environmental challenges.

FAQ

What does GCS stand for in GCS Cabinets?

GCS stands for “Modular Low-Voltage Switchgear” (derived from its Chinese designation), referring to its modular design for low-voltage power distribution systems.

What types of facilities use GCS Cabinets?

GCS Cabinets are widely used in industrial plants (manufacturing, mining, oil and gas), commercial buildings (hospitals, malls, offices), data centers, and infrastructure projects requiring flexible, reliable power distribution.

How do GCS Cabinets improve energy efficiency?

They reduce energy loss through optimized busbar designs, enable targeted power distribution to avoid waste, and integrate with monitoring tools to track usage and identify inefficiencies.

Can GCS Cabinets be used outdoors?

Yes, many GCS Cabinets have weatherproof enclosures (IP65 or higher) that resist dust, rain, and temperature extremes, making them suitable for outdoor applications.

How often should GCS Cabinets be maintained?

Routine maintenance, including inspections, cleaning, and component checks, is recommended every 6–12 months. Their modular design makes maintenance quick and minimizes downtime.