102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86 177 0691 9203 [email protected]

Overview

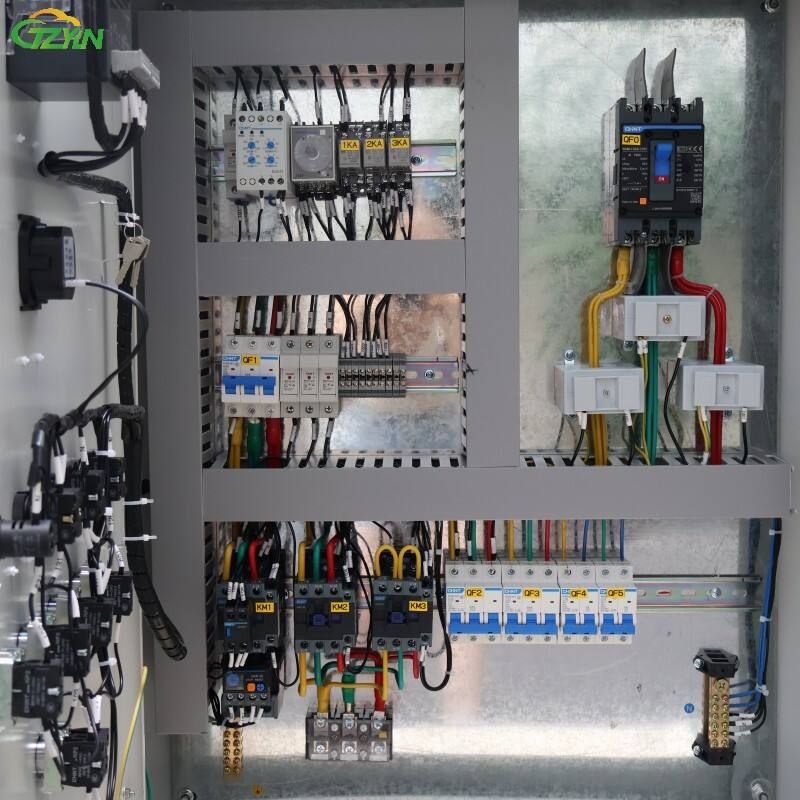

The star-delta pump motor starter cabinet functions as a critical power distribution cabinet for pump motor control. Combining

the roles of an industrial distribution box and electric power box, it manages motor startup by switching between star and delta

modes to minimize grid strain. Equipped with protective components in its circuit breaker box, it ensures stable operation, making

it essential for water supply, sewage, and industrial pumping systems.

Core Components and Features

This starter cabinet can provide the star-delta starting method for both large and small motors. During motor startup, it first adopts

a star connection to reduce the starting current and minimize the impact on the power grid; once the motor speed rises to a certain

sufficient level, it automatically switches to a delta connection to enable the motor to operate normally. This starting method effectively

protects the motor, extends its service life, and reduces energy consumption during startup. Its built-in monitoring system monitors

the motor's operating status in real time, including parameters such as current, voltage, and temperature. Once anomalies like excessive

current or overtemperature are detected, it can issue an alarm signal promptly, making it convenient for staff to quickly troubleshoot

and resolve issues, thus ensuring the continuity of production.

Design and Compliance

Design:

The cabinet uses a steel electric board and reinforced enclosure to resist dust, moisture, and mechanical impact—ideal for harsh

industrial environments. Internal wiring is organized for easy access, with clear labeling on the electrical distribution panel to simplify

troubleshooting and upgrades.

Compliance:

It meets safety standards for low voltage power cabinet systems, with components like breakers and contactors certified for industrial

use. Compliance with global electrical norms ensures it operates safely in diverse regions, reducing risks of electrical hazards.

|

|

|

Key Advantages

Safe Motor Protection:

The integrated circuit breaker box, along with built-in safeguards like overcurrent detectors, acts promptly to block overloads and

short circuits. This not only shields motors from damage caused by excessive current but also eliminates electrical hazards, protecting

on-site personnel and ensuring the entire pump system operates safely.

Energy-Efficient Starting:

Its core star-delta conversion technology cuts startup current significantly, easing the strain on the power grid. The power distribution

cabinet’s precise power management further enhances this effect, reducing unnecessary energy waste during the motor’s startup phase.

Durable Build:

Crafted from high-quality carbon steel and fitted with a rugged enclosure, the cabinet resists dust, moisture, and mechanical wear. Even

in harsh industrial environments with temperature fluctuations or vibrations, it maintains stable performance, extending its lifespan and

minimizing the need for frequent replacements.

Industrial Compatibility:

As a dedicated industrial distribution box, it features flexible interfaces that enable seamless integration with water supply pumps, sewage

pumps, and other pump types, adapting perfectly to diverse industrial pumping scenarios without extra modifications.

Parameter

Motor Power Range |

7.5kW - 75kW |

Starting Mode |

Star-delta (automatic conversion) |

Rated Voltage |

380V/415V (3-phase, low voltage) |

Protection Level |

IP54 |

Operating Temperature |

-10°C to +50°C |

Application Scenarios

Industrial Water Supply:

It powers critical equipment like boiler feed pumps and cooling water circulation systems in factories. The built-in power

distribution cabinet regulates current and voltage precisely, ensuring pump motors run stably without sudden shutdowns—

this stability is key to maintaining consistent water flow, which directly supports smooth production processes like machinery

cooling and production-line cleaning.

Sewage Treatment Plants:

It controls submersible sewage pumps that handle waste water. When pumps get clogged by debris (a common issue in sewage

work), the integrated circuit breaker box triggers quickly to cut off power, preventing motor overloads or burnout. This protection

ensures uninterrupted waste water collection and treatment, avoiding system backups.

Building Plumbing Systems:

It manages water circulation pumps in commercial buildings (e.g., malls, office towers). Through the electrical distribution panel,

it enables star-delta starting—this reduces startup current, preventing voltage drops in the building’s internal power grid that could

disrupt other electrical devices like elevators or lighting.

Agricultural Irrigation:

It operates large-scale irrigation pumps for farmlands. Its industrial distribution box uses durable, weather-resistant materials,

withstanding outdoor elements like rain, dust, and temperature changes. This rugged design ensures pumps work reliably during

planting and harvesting seasons, delivering steady water to crops for healthy growth.