102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86 177 0691 9203 [email protected]

Overview

This state-of-the-art Explosion Proof PLC Control Cabinet is engineered to be the critical nerve center for sophisticated automated processes

operating within classified hazardous locations. Utilizing the highly robust "Ex d" flameproof protection concept, the heavy-duty

enclosure is designed to safely contain any potential internal spark or catastrophic explosion, effectively preventing the ignition of the volatile

external atmosphere. It is meticulously manufactured to precisely house core automation hardware, notably the industry-leading Allen-Bradley

PLC, thereby guaranteeing uninterrupted logical control, seamless data processing, and highly precise signal handling. Functioning as a

comprehensive Explosion Proof Automation System, this cabinet delivers unparalleled operational reliability, significantly simplified long-term

maintenance, and unwavering safety adherence, establishing it as the definitive, high-performance solution for industry leaders prioritizing both

regulatory compliance and superior operational integrity.

Core Components and Features

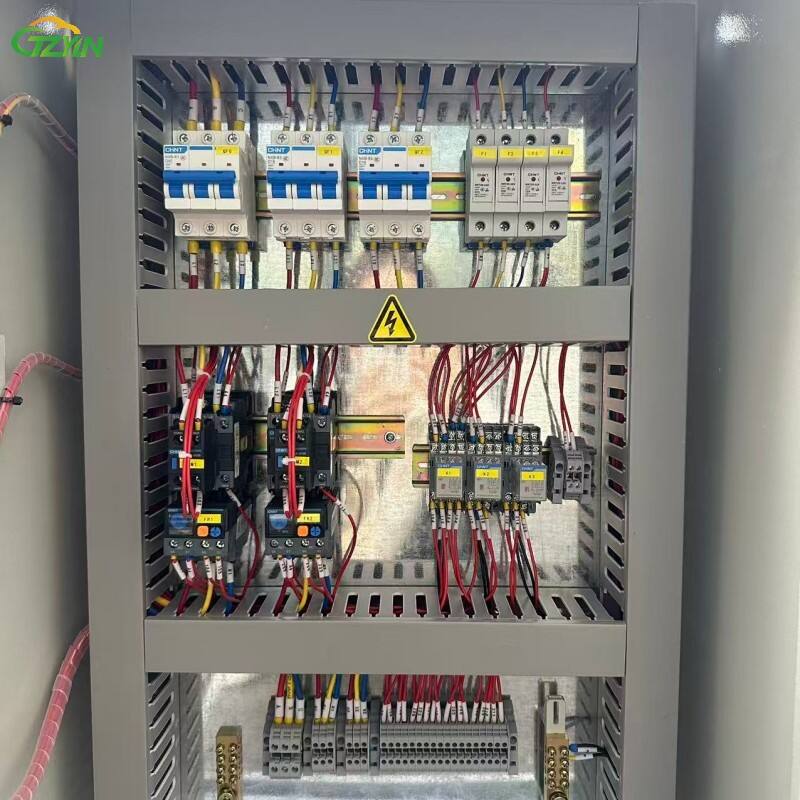

At the operational core of this unit lies a highly sophisticated Allen-Bradley PLC system, renowned as the industry-leading automation platform.

This powerful controller is responsible for the execution of complex control algorithms, intricate sequential logic, and critical real-time process

management tasks across the facility. Highly integrated input/output (I/O) modules and specialized signal transfer components are meticulously

utilized to manage data flow with exceptional efficiency, accurately converting diverse field signals into actionable, high-integrity data for the

central PLC. Consequently, the fully assembled cabinet effectively functions as a consolidated Hazardous Area Control Panel, expertly facilitating

rapid signal acquisition, dependable data transmission, and crucial safety equipment interlocking. To ensure absolute operational safety, critical

safety components, including intrinsically safe barriers (where necessary) and high-quality wiring terminals, are integrated to stringently

maintain system integrity. This meticulous, professional assembly guarantees that the Explosion Proof PLC Control cabinet delivers accurate,

reliable, and completely safe automation control across every connected piece of field equipment and process.

Design and Compliance

Design:

The core of the system is the heavy-duty Stainless steel control box, fabricated using high-grade, corrosion-resistant steel. This robust

construction is essential for its primary function as an Explosion-Proof box. The enclosure utilizes the Ex d (flameproof) protection technique,

meaning its joints and structure are engineered to withstand the pressure of an internal explosion and prevent the propagation of flames or

hot gases to the external atmosphere. This physical design ensures the absolute safety and longevity of the internal electrical components

in harsh industrial environments.

Compliance:

This system is manufactured and rigorously tested to comply with stringent international standards, notably as an ATEX Certified Control

Cabinet and typically meeting IECEx requirements. Certification ensures that the cabinet is suitable for designated Zone 1 and Zone 2

hazardous areas. Furthermore, the integration of components like the Allen-Bradley PLC Ex d Switchboard adheres to specific industrial safety

codes, providing end-users with documented proof of global compliance, which is vital for multinational operations and regulatory approval.

|

|

|

Key Advantages

Uncompromised Safety Assurance

As a certified Explosion Proof PLC Control cabinet, its primary benefit is the guarantee of safety in flammable and explosive environments.

The flameproof design and compliant sealing mechanisms eliminate the risk of ignition sources from internal electrical equipment, providing

critical protection for personnel and assets.

Superior Component Reliability

Integration of the industry-standard Allen-Bradley PLC ensures peak performance, reliable operation, and long-term support. This choice

of a premium, proven control platform maximizes uptime and reduces the total cost of ownership compared to less robust solutions,

establishing it as a highly dependable Hazardous Area Control Panel.

Durability and Longevity

The use of a Stainless steel control box provides exceptional resistance to corrosion, harsh chemicals, and extreme temperatures, which

are common in many hazardous and outdoor industrial settings. This superior build quality extends the product's service life, minimizing

replacement cycles and maintenance needs for the Explosion-Proof box.

Seamless System Integration

Designed to be the control hub, this Explosion Proof Automation System simplifies wiring and integration by accommodating all I/O and

communication modules in a single, safe enclosure. This centralized approach streamlines commissioning and maintenance of the entire

automated facility.

Parameter

Protection Type |

Flameproof (Ex d) |

Material |

High-Grade Stainless Steel |

Controller Brand |

Allen-Bradley |

Protection Level |

IP65(customizable) |

Customization |

Available |

Certifications |

ATEX, IECEx (Standard) |

Rated Voltage |

Up to 690V AC |

Application Scenarios

Oil & Gas Exploration and Processing

Used extensively in upstream drilling platforms, refineries, and pipelines as the Hazardous Area Control Panel for critical processes like pump

control, valve interlocking, and flow rate monitoring. The cabinet's ability to safely operate in environments categorized as Zone 1 or Zone 2

is paramount for controlling wellheads and compressor stations without risk of sparking.

Chemical and Petrochemical Manufacturing

Essential for regulating reactors, mixers, and processing units where highly volatile solvents and chemicals are handled. The ATEX Certified

Control Cabinet ensures that the sophisticated logic of the Allen-Bradley PLC Ex d Switchboard manages complex batch sequences and safety

interlocks, maintaining precise control over exothermic reactions and material transfers.

Pharmaceutical and Fine Chemical Production

Applied in areas where solvent vapors are present during drying, coating, or extraction processes. The system provides a safe platform for

automated quality control and process parameter adjustments, ensuring product integrity and regulatory compliance, all while operating safely

within the requirements of the Explosion Proof Automation System standard.

Grain Processing, Storage, and Dust Environments

Beyond gas environments, the flameproof and robust Explosion-Proof box is suitable for areas with combustible dust (e.g., flour mills, coal

handling facilities). It safely houses the control logic for conveyor systems and silo monitoring, preventing ignition from electrical equipment

failures, benefiting from the non-corrosive properties of the Stainless steel control box.