102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86 177 0691 9203 [email protected]

Recently, a batch of specialized "pre-configured" power distribution cabinets (Model XL-21), customized specifically for a high-profile

Rwanda building's water treatment system, successfully passed rigorous factory quality inspections. Serving as the essential power

front-end for the entire project, these units are designed to provide stable power interfaces and critical control support for a variety

of subsequent installations, including heavy-duty circulation pumps, advanced filtration units, and automated dosing devices. By

acting as the core electrical hub, these terminals ensure the seamless transition to a fully automated water management system.

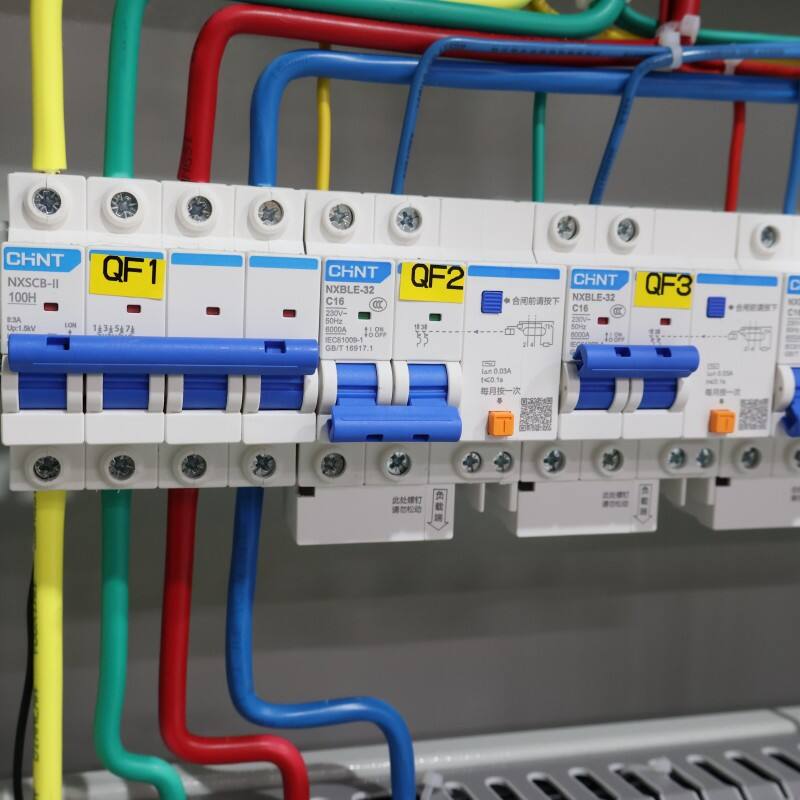

The cabinets successfully integrate the high efficiency of a power distribution unit (pdu) with stringent industrial-grade protection

standards. To ensure long-term reliability in the East African market, the core components feature top-tier international brands like

CHNT. The main switches offer superior short-circuit protection (Icu/Ics) and high surge resistance, a critical feature that allows

the equipment to adapt perfectly to the fluctuating grid environments often encountered in developing infrastructure. Furthermore,

the modular branch design (labeled QF1 through QF8) ensures that each water treatment unit operates on an independent circuit,

significantly enhancing system redundancy and preventing a single localized fault from causing a total system shutdown.

Strategically, our engineering team emphasizes the "pre-provisioning" concept to solve common pain points in international construction.

Each cabinet comes equipped with pre-installed DIN rails and standardized terminal blocks organized for high-density wiring. This

allows on-site technical teams in Rwanda to rapidly expand the system or integrate sophisticated automation control modules—such

as PLC controllers or smart sensors—without the need to alter the original main circuitry. This modular design not only significantly

shortens the initial installation timelines but also lowers the technical barrier and cost for long-term maintenance and future upgrades.

In terms of physical craftsmanship, the enclosures are built to withstand demanding utility environments. They utilize high-strength

anti-corrosion coatings applied through an electrostatic spraying process and feature precise industrial sealing to ensure excellent

dustproofing and heat dissipation. These features are vital for maintaining the longevity of internal electronics in enclosed equipment

rooms. As an international digital commerce operator dedicated to high-end industrial exports, we remain committed to providing

professional electrical solutions that strictly meet IEC international standards. By delivering these robust "pre-configured" solutions,

we continue to support the sustainable growth of global infrastructure and water resource management.