Revolutionizing Industrial Control Systems with Integrated Network Solutions

The modern industrial landscape is experiencing a dramatic transformation as automation and connectivity reshape manufacturing processes. At the heart of this evolution lies a crucial innovation: integrating Ethernet switches directly into PLC cabinets. This integration represents more than just a space-saving measure – it's a fundamental shift in how we approach industrial networking and control systems.

The seamless marriage of Ethernet switches and PLC cabinets is enabling unprecedented levels of efficiency, reliability, and control in industrial operations. As we delve deeper into this topic, we'll explore the compelling reasons why this integration has become essential for forward-thinking industrial operations.

Core Benefits of PLC Cabinet Ethernet Switch Integration

Enhanced Space Utilization and Organization

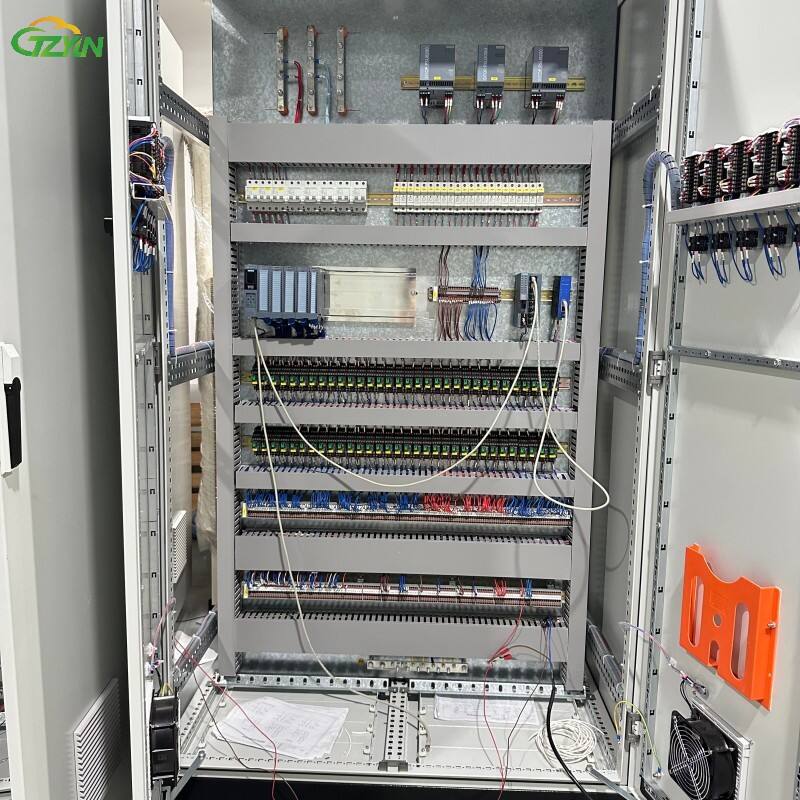

When Ethernet switches are integrated directly into PLC cabinets, facilities gain significant advantages in spatial efficiency. Traditional setups often require separate enclosures for networking equipment, leading to cluttered control rooms and increased wall space requirements. By consolidating these components within the PLC cabinet, organizations can optimize their space utilization while maintaining a cleaner, more organized industrial environment.

The integrated approach eliminates the need for additional mounting hardware, reducing the overall footprint of control system installations. This consolidation particularly benefits facilities with limited space or those looking to expand their automation capabilities without physical expansion.

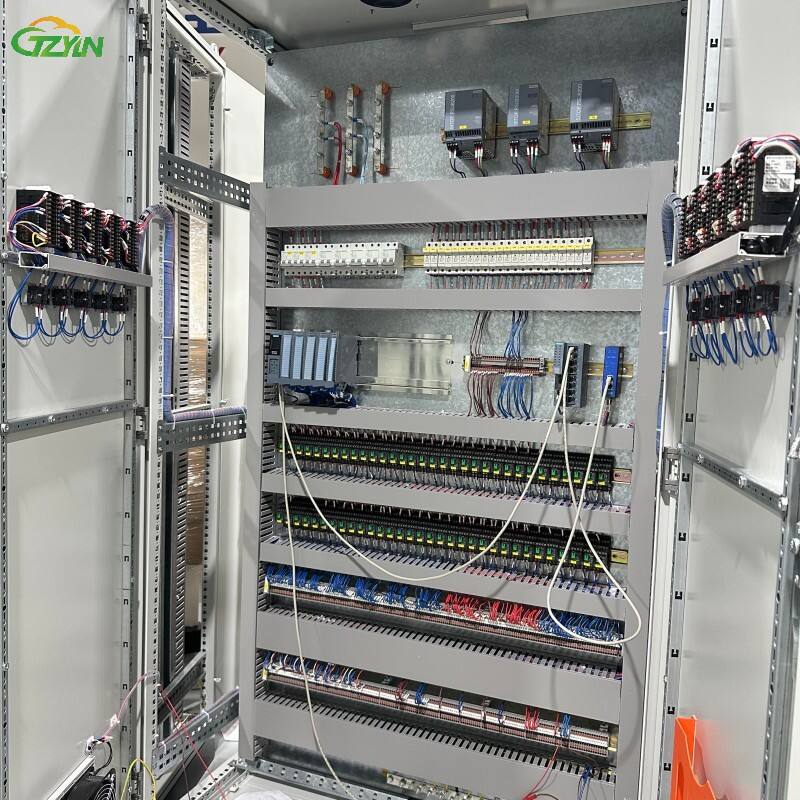

Improved System Protection and Environmental Control

Housing Ethernet switches within PLC cabinets provides an additional layer of protection against harsh industrial environments. The controlled environment within the cabinet shields sensitive networking equipment from dust, moisture, temperature fluctuations, and other potentially harmful elements commonly found in manufacturing settings.

This protective integration extends the lifespan of both the switches and associated networking components while reducing maintenance requirements and potential points of failure. The shared environmental control system maintains optimal operating conditions for all equipment, ensuring consistent performance and reliability.

Technical Advantages of Integrated Solutions

Simplified Cable Management and Connectivity

Integrating Ethernet switches into PLC cabinets dramatically simplifies cable management. With shorter cable runs and more direct connections, the risk of signal degradation decreases while network reliability improves. This integration allows for more organized cable routing, reducing electromagnetic interference and improving overall system performance.

The proximity of switches to PLCs also enables better cable organization, making maintenance and troubleshooting more straightforward. Technicians can easily trace connections and perform updates without navigating complex cable runs between separate enclosures.

Enhanced Network Performance and Reliability

Direct integration leads to optimized network architecture with reduced latency and improved data transmission speeds. The shortened distance between Ethernet switches and PLCs minimizes signal travel time, resulting in faster communication and more responsive control systems.

This setup also reduces the potential points of failure in the network infrastructure, leading to increased system reliability and reduced downtime. The controlled environment within the cabinet further ensures consistent network performance across all connected devices.

Cost and Maintenance Considerations

Reduced Installation and Infrastructure Costs

The integration of Ethernet switches into PLC cabinets yields significant cost savings across multiple areas. Initial installation costs decrease due to reduced cabling requirements and simplified mounting needs. The consolidated approach eliminates the expense of separate enclosures and additional environmental control systems.

Organizations also benefit from reduced labor costs during installation, as technicians can complete the entire setup within a single cabinet. This integration streamlines the installation process and reduces the complexity of future system modifications.

Streamlined Maintenance Procedures

Centralized equipment placement within PLC cabinets simplifies maintenance routines and reduces service time. Technicians can access all critical components from a single location, making regular inspections and repairs more efficient. This integration also facilitates better monitoring of equipment health and early detection of potential issues.

The shared environmental control system means maintaining consistent operating conditions requires less effort and resources. Regular maintenance tasks can be scheduled and performed simultaneously for all cabinet components, optimizing maintenance workflows and reducing operational disruptions.

Future-Proofing Industrial Networks

Scalability and Expansion Capabilities

Integrated Ethernet switches in PLC cabinets provide a foundation for future network expansion. The modular nature of modern industrial networking equipment allows for easy upgrades and additions as operational needs evolve. This flexibility ensures that organizations can adapt their control systems without major infrastructure changes.

The consolidated approach also simplifies the implementation of new technologies and protocols, as the integrated system can more readily accommodate updates and modifications to meet changing industry standards.

Industry 4.0 Compatibility

The integration of Ethernet switches within PLC cabinets aligns perfectly with Industry 4.0 principles and requirements. This setup facilitates the implementation of advanced features such as real-time data analytics, machine learning capabilities, and improved connectivity for Industrial Internet of Things (IIoT) devices.

As industrial operations continue to embrace digital transformation, integrated networking solutions provide the necessary infrastructure to support smart manufacturing initiatives and enhanced automation capabilities.

Frequently Asked Questions

How does integrating Ethernet switches affect PLC cabinet cooling requirements?

The addition of Ethernet switches to PLC cabinets typically results in minimal impact on cooling requirements. Modern industrial Ethernet switches are designed to be energy-efficient and generate relatively little heat. However, proper thermal management planning should account for the combined heat load of all components to ensure optimal operating temperatures are maintained.

What security considerations should be addressed when integrating Ethernet switches in PLC cabinets?

Security considerations include implementing proper physical access controls to the cabinet, utilizing network segmentation and VLANs, enabling appropriate security protocols, and ensuring firmware is regularly updated. The integrated approach actually enhances security by reducing external access points and centralizing network management.

Can existing PLC cabinets be retrofitted to accommodate Ethernet switches?

Most PLC cabinets can be retrofitted to accommodate Ethernet switches, provided there is adequate space and proper consideration for power requirements and heat dissipation. The retrofit process should include a thorough assessment of cabinet specifications, current load, and future expansion needs to ensure successful integration.