Understanding Modern Lighting Distribution Systems

A lighting distribution cabinet serves as the central nervous system of any building's lighting infrastructure. These sophisticated electrical panels ensure that power is efficiently distributed across various lighting circuits while maintaining optimal balance between phases. In commercial and industrial settings, where lighting demands can be substantial, these cabinets play a crucial role in managing and distributing electrical loads effectively.

The proper functioning of a lighting distribution cabinet directly impacts energy efficiency, system reliability, and the longevity of lighting installations. By carefully balancing three-phase lighting loads, these cabinets prevent issues like voltage fluctuations, system overloads, and unnecessary wear on electrical components.

Core Components of Lighting Distribution Cabinets

Main Circuit Breakers and Switches

At the heart of every lighting distribution cabinet lies the main circuit breaker, which serves as the primary safety mechanism and power control point. This component monitors incoming power and provides immediate protection against overloads and short circuits. Modern cabinets feature sophisticated circuit breakers with adjustable trip settings to accommodate varying load requirements.

The main switches in a lighting distribution cabinet allow for manual control and isolation of different lighting circuits. These switches are designed for frequent operation and must meet strict safety standards to ensure reliable performance under various conditions.

Bus Bars and Power Distribution Components

Bus bars form the backbone of power distribution within the cabinet, carrying substantial electrical currents to various circuit breakers and switches. These copper or aluminum bars are precisely sized to handle the maximum expected current while maintaining minimal power losses. The arrangement of bus bars plays a crucial role in heat dissipation and overall system efficiency.

Supporting components such as insulators, mounting brackets, and connection terminals ensure secure and reliable power distribution. These elements must withstand thermal stress, vibration, and potential short-circuit forces while maintaining proper electrical clearances.

Phase Balancing Mechanisms

Automated Load Distribution Systems

Modern lighting distribution cabinets incorporate sophisticated automated systems that continuously monitor and adjust load distribution across phases. These systems use microprocessor-controlled circuits to measure current flow and power consumption in real-time, making instantaneous adjustments to maintain optimal balance.

The automation technology employs advanced algorithms to predict load patterns and preemptively redistribute power, ensuring stable operation even during sudden changes in lighting demands. This dynamic approach to load balancing significantly reduces the risk of phase imbalance and its associated problems.

Manual Balancing Controls and Indicators

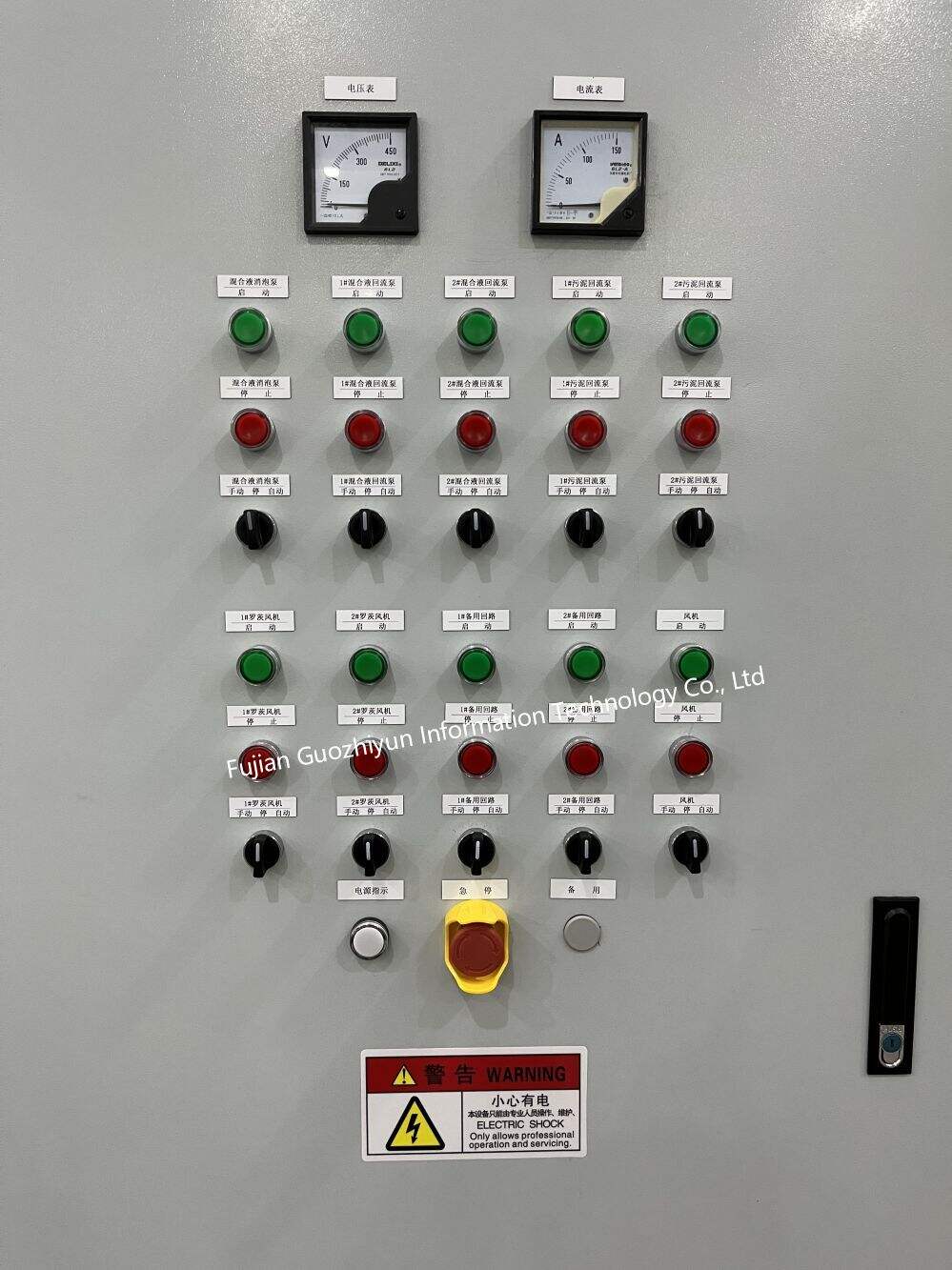

Despite automation, lighting distribution cabinets retain manual balancing capabilities for maintenance and emergency situations. These controls allow technicians to manually adjust phase distribution when necessary. Clear indicators and monitoring displays provide real-time feedback on phase loads, helping operators make informed decisions during manual adjustments.

Visual indicators such as LED displays and analog meters show current distribution across phases, making it easy to identify and correct any imbalances. This hybrid approach of automated and manual controls ensures reliable operation under all circumstances.

Smart Features and Integration Capabilities

Digital Monitoring and Control Systems

Contemporary lighting distribution cabinets are equipped with advanced digital monitoring systems that provide comprehensive data on power consumption, load patterns, and system performance. These systems can integrate with building management software, enabling remote monitoring and control of lighting circuits.

The digital infrastructure allows for detailed analysis of energy usage patterns, helping facility managers optimize lighting schedules and identify opportunities for energy savings. Real-time alerts and notifications ensure quick response to potential issues before they escalate into serious problems.

Energy Management and Optimization

Smart features within lighting distribution cabinets facilitate sophisticated energy management strategies. These include automated scheduling, daylight harvesting integration, and demand response capabilities. The cabinet's intelligence can adjust lighting levels based on occupancy patterns, natural light availability, and peak demand periods.

Energy optimization algorithms continuously analyze usage data to suggest improvements in load distribution and scheduling. This proactive approach helps maintain optimal system efficiency while reducing operational costs and environmental impact.

Maintenance and Troubleshooting Considerations

Preventive Maintenance Protocols

Regular maintenance of lighting distribution cabinets is essential for ensuring long-term reliability and efficiency. This includes periodic inspection of all components, thermal imaging to detect potential hotspots, and verification of connection integrity. Maintenance schedules should be based on usage patterns and environmental conditions.

Preventive measures such as cleaning, tightening connections, and calibrating sensors help prevent unexpected failures and maintain optimal performance. Documentation of maintenance activities and component replacement histories aids in predicting potential issues before they occur.

Common Issues and Resolution Strategies

Understanding common problems and their solutions is crucial for maintaining lighting distribution cabinets. Issues may include phase imbalance, overheating, circuit breaker trips, or communication failures in smart systems. Quick identification and resolution of these problems prevent extended downtime and potential damage.

A systematic approach to troubleshooting, supported by detailed documentation and diagnostic tools, enables efficient problem resolution. Regular training for maintenance personnel ensures they stay current with the latest technologies and best practices.

Frequently Asked Questions

How often should a lighting distribution cabinet be inspected?

Professional inspection of a lighting distribution cabinet should be conducted at least annually, with more frequent checks recommended for high-usage environments or critical installations. Regular visual inspections by facility staff should be performed monthly, checking for signs of wear, unusual sounds, or temperature variations.

What causes phase imbalance in lighting distribution systems?

Phase imbalance typically occurs due to uneven distribution of single-phase lighting loads, failed circuit components, or improper initial setup. External factors such as building modifications or changes in lighting fixtures without proper load calculation can also contribute to phase imbalance.

Can existing lighting distribution cabinets be upgraded with smart features?

Many existing lighting distribution cabinets can be retrofitted with smart monitoring and control systems. The upgrade typically involves installing current sensors, communication modules, and a central control unit. However, the feasibility and extent of upgrades depend on the cabinet's age, design, and available space for new components.

What are the signs of an overloaded lighting distribution cabinet?

Common signs of overloading include frequent circuit breaker trips, unusual heat generation, buzzing sounds from the cabinet, flickering lights, and visible damage to components. Regular monitoring of load levels and thermal conditions can help detect potential overload situations before they cause system failure.