102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86 177 0691 9203 [email protected]

Overview

This 250A distribution cabinet, a dedicated GGD cabinet, serves as the core power supply board for textile mill drawing machines. It regulates

3-phase electrical flow, converting and distributing power to meet the high-demand, continuous operation of drawing machines. With robust

construction, it functions as a reliable circuit breaker switchboard, preventing overloads or short circuits common in textile production. Ideal

for textile workshops, it ensures consistent power, minimizing downtime and supporting efficient drawing processes.

Core Components and Features

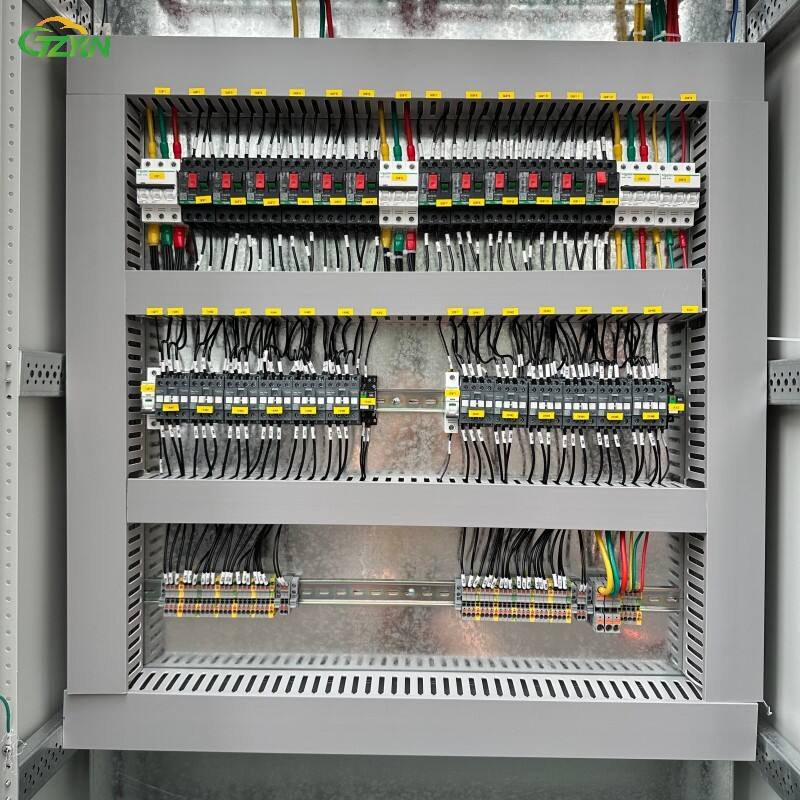

The cabinet features key components tailored for textile drawing machines: a high-performance circuit breaker switchboard to cut off faulty currents,

preventing damage to drawing equipment; 3-phase busbars for balanced power distribution, critical for the stable rotation of drawing machine motors;

and terminal blocks ensuring secure connections with drawing machine circuits. As an industrial electrical panel, it monitors real-time voltage and

current, alerts on anomalies, and controls power on/off for drawing machines. This power distribution panel integrates protection (overload, short-circuit)

and regulation, ensuring the drawing machine’s motor runs smoothly without interruptions.

Design and Compliance

Design:

The GGD cabinet adopts a sealed, dust-resistant enclosure, addressing textile mills’ fiber-laden environment to avoid component clogging. Ventilation

slots are optimized for heat dissipation, coping with the continuous operation of drawing machines. Its modular design allows easy access to internal

components, simplifying maintenance—vital for minimizing production halts in textile workshops.

Compliance:

It meets strict standards for industrial electrical panels, including 3-phase electrical safety norms and textile machinery power supply regulations.

Certified for electrical distribution cabinet safety, it ensures compatibility with drawing machine voltage requirements, adhering to global textile

industry electrical standards.

|

|

|

Key Advantages

Tailored Reliability:

As a 250A distribution cabinet, it leverages high-quality internal components and stable 3-phase power regulation to deliver consistent electricity

for drawing machines’ non-stop operation. This minimizes unplanned shutdowns in textile production, directly boosting output efficiency and

reducing losses from interrupted workflows.

Enhanced Safety:

Equipped with a sensitive circuit breaker switchboard and multi-layer 3-phase protection, it detects overloads or short circuits in milliseconds,

triggering instant power cuts. This not only shields expensive drawing equipment from damage but also prevents electrical hazards, ensuring

worker safety in busy textile workshops.

Textile-Ready Design:

Its sealed enclosure blocks fiber dust—common in textile mills—from clogging components, while optimized ventilation slots dissipate heat from

continuous operation. This design adapts to the harsh, high-humidity environment, ensuring long-term, trouble-free performance.

Efficient Integration:

Compatible with major drawing machine brands and models, this power supply board features modular connection ports, simplifying installation

into existing textile production lines. It reduces setup time, letting factories resume operations quickly after deployment.

Parameter

Rated Current |

250A |

Frequency |

50Hz |

Rated Voltage |

380V (3-Phase AC) |

Protection Level |

IP55 |

Cabinet Material |

Galvanized steel |

Application Scenarios

Factories:

In manufacturing facilities such as automobile plants, machinery processing workshops, and electronics assembly factories, the cabinet distributes

power to high-power equipment like stamping machines, conveyor belts, and precision lathes. It stabilizes current output to avoid equipment

malfunctions caused by power fluctuations, ensuring smooth and uninterrupted production—critical for meeting daily output targets.

Commercial Buildings:

In shopping malls, office complexes, and high-end hotels, it supplies power to multi-system loads including lighting, central HVAC, elevators,

and commercial refrigeration. During peak periods (e.g., weekend shopping sprees or weekday office hours), it dynamically adjusts power

allocation to high-demand areas, preventing local overload and ensuring a comfortable and reliable environment for customers and employees.

Data Centers:

As a key part of data center power infrastructure, it manages power delivery to servers, storage arrays, and cooling systems. It works in tandem

with UPS (Uninterruptible Power Supply) systems to achieve seamless power switching in case of sudden outages, avoiding data loss or system

crashes—essential for safeguarding sensitive data and maintaining continuous service for users.

Infrastructure Projects:

Applied in large-scale public infrastructure like subway stations, airports, and municipal water treatment plants, it supports critical electrical

systems. For example, in subway operations, it powers traction systems and platform lighting; in airports, it supplies stable power to terminal

security check equipment and baggage handling systems—ensuring these 24/7 operational facilities run reliably without interruptions.